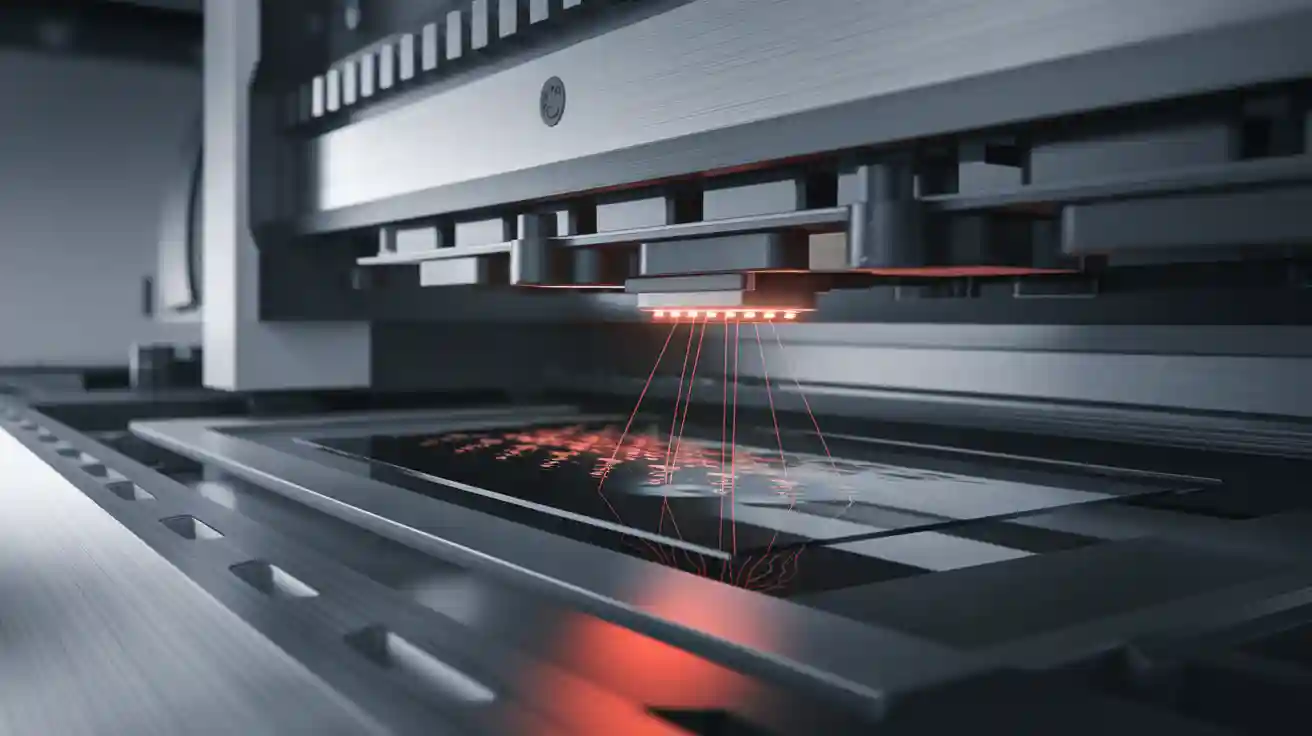

An infrared emitter for glass press delivers targeted heat for glass forming, bending, and coating processes. Manufacturers rely on this technology to achieve precise temperature control and uniform heating, which minimizes breakage and boosts optical clarity. YFR provides advanced infrared heating solutions that enable faster thermal response, reduced energy consumption, and improved product yield. The infrared emitter for glass press offers significant advantages over traditional heating methods by ensuring efficient heat transfer and consistent quality across production lines.

Infrared emitters provide fast, targeted heat that improves glass forming, bending, and coating processes.

Medium-wave infrared emitters match glass absorption well, ensuring even heating and reducing defects.

YFR’s infrared emitters offer energy savings, rapid response times, and precise temperature control.

Special designs like gold reflectors and carbon emitters boost heating efficiency and product quality.

Proper installation and safety measures, including protective eyewear, are essential for safe operation.

Regular maintenance and quick troubleshooting keep emitters working efficiently and extend their lifespan.

Customizable and modular infrared systems allow manufacturers to tailor heating to specific glass pressing needs.

Infrared technology outperforms traditional heating by reducing energy use, speeding production, and enhancing product consistency.

An infrared emitter for glass press is a specialized heating device engineered to deliver targeted infrared energy to glass during pressing operations. This technology uses quartz glass tubes, often with gold or white oxide reflectors, to produce controlled infrared radiation. The emitter heats glass surfaces efficiently, supporting processes such as molding, embossing, and laminating. Medium-wave infrared radiation is particularly effective for glass, as it is readily absorbed by the material, ensuring uniform surface heating. Manufacturers select these emitters for their ability to provide rapid thermal response and precise temperature control, which are essential for high-quality glass production.

Tip: Medium-wave infrared emitters excel in glass pressing because glass absorbs this wavelength efficiently, resulting in consistent heating and reduced risk of defects.

YFR stands out in the industrial infrared heating market by offering advanced quartz glass infrared heaters. Their product range includes short-wave and medium-wave lamps with single or dual quartz tubes. These designs enhance mechanical stability and allow for longer emitter lengths, up to 3.5 meters. YFR integrates gold reflectors to maximize radiation efficiency, ensuring that heat is directed precisely where needed. The company’s strict quality control and commitment to innovation position it as a reliable provider for demanding glass pressing applications.

Infrared emitters serve several critical functions in glass pressing environments:

Deliver efficient heating and pre-heating for glass and metals, which is vital for forming and shaping.

Facilitate molding, embossing, and laminating by providing uniform infrared radiation.

Support precise temperature control during processes like annealing, which helps reduce stress in glass.

Optimize heating stages in laminated glass production, ensuring effective bonding with PVB plastic foil.

Enable rapid response times and high energy absorption, especially with carbon infrared emitters.

Reduce processing time and operational costs compared to conventional heating methods.

Improve product quality by preventing defects such as skin or blister formation during coating and drying.

YFR’s infrared solutions offer controllable, energy-saving heating that outperforms traditional hot air systems. Their modular systems combine emitters with custom housings and control units, allowing manufacturers to tailor heating solutions to specific glass pressing needs. Accessories like clips and clamps simplify installation, while custom design services ensure compatibility with diverse production setups. YFR’s focus on energy efficiency and advanced control technologies helps manufacturers achieve consistent results and maintain high process quality.

Infrared emitters operate by converting electrical or chemical energy into thermal energy through a heated element, such as tungsten, quartz, or ceramic. This process results in the emission of infrared electromagnetic waves, which transfer energy primarily by radiation. The emission of these waves follows the Second Law of Thermodynamics, where heat flows from a hotter body to a cooler one. When the emitter reaches high temperatures—often between 1800°C and 2400°C—the emission of infrared radiation becomes intense and focused. The design of the emitter, including the use of gold or white oxide reflectors, directs the emission efficiently onto the glass surface.

The efficiency of this process depends on the emissivity of the glass. Materials like Pyrex, lead, and soda glass have high emissivity values, allowing them to absorb infrared radiation effectively. The wavelength of the emission plays a crucial role in the heating process. By tuning the wavelength to match the absorption characteristics of glass, manufacturers achieve faster, more stable, and energy-efficient heating. Medium-wave infrared heat, for example, penetrates glass surfaces efficiently, making it ideal for pressing, molding, and laminating. The emission of energy through radiation, combined with conduction and convection within the glass and surrounding air, ensures uniform temperature distribution.

Note: The rapid response time of infrared emitters—often reaching full operating temperature in just one second—enables precise control over the heating process. This capability reduces waiting times and increases throughput in glass manufacturing.

The following table summarizes typical operating parameters for an infrared emitter for glass press:

Parameter | Value |

|---|---|

Filament Temperature | 1800 - 2400 °C |

Power | 500 W |

Voltage | 115 V |

Heated Length | 225 mm |

Wavelength | 1.0 - 1.4 µm |

Max Power Density | 200 kW/m² |

Response Time | 1 s |

YFR modules integrate seamlessly into glass press machinery, providing optimal performance and reliability. The modular design combines infrared emitters with custom housings and advanced control units, ensuring that the emission of infrared heat is both targeted and adjustable. Engineers select the appropriate emitter type and wavelength based on the specific requirements of the glass pressing process. This customization allows for precise emission control, matching the thermal profile needed for each application.

The integration process involves mounting the infrared emitter for glass press in strategic locations within the machinery. Gold reflector technology enhances the emission direction, focusing infrared heat exactly where it is needed. Intelligent control systems, such as C power dosing and regulation, monitor and adjust the emission in real time. This approach maintains consistent temperatures, reduces energy waste, and supports automation.

YFR’s infrared modules deliver several documented performance improvements:

Performance Aspect | Documented Improvement |

|---|---|

Instant and Focused Heating | Enables precise and rapid heating, reducing stress and cracking in glass. |

Energy Efficiency | Converts over 92% of electrical energy into heat, lowering operational costs. |

Process Speed and Throughput | Shortens production cycles and increases output due to rapid response times. |

Product Quality | Ensures uniform heating, reducing defects and material waste. |

Durability and Maintenance | Lifespan exceeds 10,000 hours, minimizing downtime. |

Robust Design | IP65 rating ensures reliable operation in harsh environments. |

Customization | Supports seamless integration and compliance with automation systems. |

The emission of infrared heat from YFR modules supports a wide range of temperature requirements, from as low as 75°C up to over 2400°C, depending on the glass type and process. This flexibility allows manufacturers to handle everything from delicate annealing to high-temperature forming. The robust design, combined with advanced emission control, ensures long service life and minimal maintenance.

Tip: Customizable specifications and modular integration make YFR infrared emitters suitable for both new installations and retrofits, supporting evolving production needs and compliance standards.

Manufacturers value efficiency in every stage of glass pressing. Infrared emitters deliver rapid and targeted heating, which leads to significant energy savings. The emission of infrared heat reaches full power within 1-2 seconds, allowing glass presses to achieve the desired temperature almost instantly. This fast response time reduces preheating periods and minimizes energy waste. Quartz infrared lamps, especially those with gold reflectors, provide stable and uniform emission, ensuring that heat is directed precisely onto the glass surface.

Rapid emission of infrared heat shortens production cycles.

Uniform emission reduces temperature fluctuations and energy loss.

Modular systems from YFR optimize the emission process, matching the heat output to the specific needs of each application.

The twin tube design of many infrared emitters enhances the stability and uniformity of emission. This design ensures that every part of the glass receives consistent infrared heat, which is essential for efficient processing. The ability to control emission with high accuracy (±1 ℃) further supports energy efficiency and process reliability.

Tip: Fast response and uniform emission help manufacturers lower operational costs while maintaining high throughput.

Consistent product quality depends on precise and uniform heating. Infrared emitters excel in this area by providing stable emission across the entire glass surface. The emission of infrared heat penetrates the material evenly, reducing the risk of defects such as bubbles, cracks, or uneven surfaces. Gold reflector technology enhances the direction and intensity of emission, ensuring that every section of the glass receives the same level of heat.

A table below highlights the impact of uniform emission on product quality:

Quality Factor | Impact of Infrared Emission |

|---|---|

Surface Uniformity | Even emission prevents warping |

Optical Clarity | Stable emission reduces defects |

Structural Integrity | Controlled emission minimizes stress |

Manufacturers can arrange infrared heating lamps to provide emission from multiple sides, further improving uniformity. This approach supports the production of high-quality glass products with fewer rejects and less material waste.

Advanced process control is a hallmark of modern glass pressing. Infrared emitters offer precise control over emission, allowing operators to adjust the intensity and duration of infrared heat as needed. Intelligent control units, such as those provided by YFR, monitor emission in real time and make automatic adjustments to maintain optimal conditions.

Accurate emission control supports repeatable results.

Flexible installation options allow for emission to be tailored to different glass types and thicknesses.

Real-time monitoring ensures that emission remains within set parameters, reducing the risk of overheating or underheating.

Compared to traditional heating methods, infrared heat provides superior process control. Conventional systems often struggle with slow response times and uneven emission, leading to inconsistent results. Infrared technology, with its rapid and uniform emission, enables manufacturers to achieve higher precision and better overall process stability.

Note: The combination of fast emission response, uniform infrared heat, and advanced control technologies sets infrared emitters apart as the preferred solution for glass pressing.

Short-wave infrared emitters deliver the highest radiation intensity and rapid emission response, making them essential for demanding glass pressing operations. These emitters use a coiled tungsten wire housed in a quartz glass tube filled with inert gas. The design supports horizontal installation as standard, with vertical options available for specialized setups. Short-wave quartz lamps operate within a wavelength range of 1.0 to 1.4 μm, which enables fast heating and cooling cycles—often within seconds. Manufacturers rely on these emitters for processes that require high intensity and quick turnaround, such as preheating glass bottles and rapid forming.

A table below summarizes the unique features of short-wave infrared emitters:

Feature | Description |

|---|---|

Radiation Intensity | Up to 20 W/cm² |

Response Time | Seconds |

Construction | Quartz tube, tungsten coil, inert gas |

Installation | Horizontal standard, vertical on request |

Application | Fast cycle times, high intensity heating, preheating glass bottles |

Short-wave infrared emission provides powerful density and precise control, which is vital for maintaining product quality and reducing cycle times. Coatings such as gold or ceramic can be applied to the rear of the tube to direct emission and improve efficiency. The emission of visible light from quartz halogen variants requires shielding from plain sight, ensuring operator safety.

Tip: Short-wave infrared emitters excel in applications where rapid emission and high power density are critical for glass pressing and forming.

Medium-wave infrared emitters offer a wavelength range from 1.4 to 4.0 μm, which aligns closely with the absorption characteristics of glass. This makes medium-wave emission highly effective for processes such as drying coatings, surface heating, and cutting laminated glass. YFR’s medium-wave infrared emitter designs include carbon spiral filaments and quartz tubes, providing flexibility for different glass pressing requirements.

Medium-wave emission penetrates glass surfaces efficiently, enabling uniform heating and reducing the risk of defects. The gold reflector nearly doubles the effective infrared emission directed onto the glass, enhancing heating efficiency and reducing energy consumption. Operators can precisely adjust the emission to match the material and process, resulting in savings in time, energy, and operational costs.

Manufacturers choose medium-wave infrared emitters for their ability to deliver stable, targeted emission and support advanced process control. The twin-tube design and high-quality quartz construction provide mechanical and thermal stability, which is crucial for industrial glass pressing environments.

Note: Medium-wave infrared emission is ideal for drying coatings on glass, preheating car glass, and cutting laminated glass, thanks to its superior absorption and energy efficiency.

Ceramic infrared emitters utilize reflective coatings, such as ceramic or gold, to direct emission and optimize heating efficiency. These coatings are typically applied to the rear of quartz glass tubes or twin tubes, ensuring that the emission is focused precisely onto the glass surface. Ceramic coatings enhance the directionality of infrared emission, making them valuable for processes that require controlled and efficient heating.

Ceramic infrared emitters support uniform emission and help reduce energy waste by reflecting infrared energy back onto the target area. This design improves process reliability and supports consistent product quality in glass pressing applications. Manufacturers often use ceramic-coated emitters to optimize emission direction and achieve higher efficiency in specialized glass forming and laminating processes.

Tip: Ceramic coatings on infrared emitters maximize emission efficiency and support precise heating control, which is essential for advanced glass pressing operations.

Manufacturers in the glass industry often require specialized solutions to address unique production challenges. YFR recognizes this need and offers a diverse portfolio of special infrared emitter designs. These advanced products go beyond standard configurations, providing tailored performance for demanding glass pressing and forming applications.

YFR’s carbon infrared emitters deliver rapid heat-up times and precise temperature control. Their unique filament structure enables fast thermal response, which is essential for processes that demand quick adjustments. Carbon emitters excel in applications where uniform heating and energy efficiency are critical. Operators often select these emitters for tasks such as forming, laminating, and even preheating glass bottles, where consistent results and minimal energy waste are priorities.

Gold reflector infrared emitters represent another innovative solution. The gold coating on the reflector maximizes the directionality of the emitted energy. This design ensures that the majority of the infrared radiation targets the glass surface, reducing heat loss and improving process efficiency. Gold reflectors also help maintain a stable temperature profile, which is vital for achieving high optical clarity and structural integrity in pressed glass products.

Round tube infrared emitters offer flexibility in installation and application. Their cylindrical shape allows for even heat distribution around complex glass forms. These emitters integrate seamlessly into modular systems, supporting both new installations and retrofits. The round tube design also enhances mechanical stability, making it suitable for continuous operation in high-throughput environments.

Nano-reflector infrared emitters utilize advanced reflective materials at the microscopic level. This technology increases the efficiency of energy transfer by minimizing losses and focusing the infrared output precisely where it is needed. Nano-reflector designs are ideal for applications that require pinpoint accuracy and minimal thermal deviation across the glass surface.

For environments with high humidity or exposure to dust and water, YFR provides IP65-rated infrared emitters. The robust housing protects the internal components, ensuring reliable operation even in harsh industrial settings. These emitters maintain consistent performance and safety standards, making them suitable for glass pressing lines that operate under challenging conditions.

YFR’s modular infrared systems combine emitters, housings, and intelligent control units into ready-to-install packages. This modular approach allows manufacturers to customize their heating solutions based on specific process requirements. The integration of advanced control technologies, such as C power dosing and regulation, further enhances process stability and energy management.

Note: Special designs like gold reflector and medium-wave infrared emitters offer significant advantages for glass pressing. They provide superior absorption, uniform heating, and energy savings, supporting both product quality and operational efficiency.

A summary of YFR’s special infrared emitter designs and their key benefits:

Special Design | Key Benefit | Typical Application |

|---|---|---|

Carbon Emitters | Fast response, uniform heating | Forming, laminating |

Gold Reflector | Maximum energy direction, efficiency | Pressing, coating, drying |

Round Tube | Flexible installation, even distribution | Complex glass shapes |

Nano-Reflector | High precision, minimal energy loss | Specialty glass, electronics |

IP65 Rated | Protection in harsh environments | Outdoor, humid production |

Modular Systems | Customization, easy integration | All glass pressing lines |

These special infrared emitter designs enable manufacturers to optimize their glass pressing processes, ensuring consistent quality and reduced operational costs.

Selecting the right infrared emitter for glass press operations requires careful evaluation of several technical factors. Each process has unique demands, so engineers must match emitter characteristics to production requirements. The following criteria guide the selection process:

Wavelength Matching: The absorption characteristics of glass determine the optimal infrared wavelength. Medium-wave emitters, typically in the 2 to 3.5 micron range, align well with glass absorption, ensuring efficient heating.

Temperature Range: The emitter must reach and maintain the required process temperature without operating at its maximum capacity. This approach extends emitter life and ensures stable performance.

Emitter Size and Design: The physical size and shape of the emitter influence heat distribution and mechanical stability. For example, round tube designs provide even heating for complex glass shapes.

Power Rating: The selected emitter should deliver sufficient power for the application while maintaining energy efficiency.

Thermal Response Time: Fast heating and cooling cycles are essential for processes with rapid or frequent changes. Quartz tube emitters offer short ramp-up times, making them suitable for cyclical operations.

Environmental Compatibility: The emitter must withstand the production environment. Factors such as dust, humidity, and chemical exposure affect the choice between quartz, ceramic, or IP65-rated designs.

Reflector Type: Gold reflectors direct heat precisely to the target area, improving efficiency and reducing energy loss.

Material Properties: The coefficient of thermal expansion and the index of refraction of the glass influence emitter selection. These properties ensure stable performance under temperature changes.

Maintenance and Integration: Internal or external reflectors, modular housings, and easy mounting options simplify maintenance and integration into existing lines.

Tip: Consulting spectral data or testing samples helps fine-tune emitter selection for specific glass types and process requirements.

A summary table of key selection factors:

Selection Factor | Importance in Glass Pressing |

|---|---|

Wavelength | Matches glass absorption for efficiency |

Temperature Range | Ensures longevity and process stability |

Size & Design | Affects heat distribution and integration |

Power Rating | Delivers required energy efficiently |

Response Time | Supports fast, precise process control |

Environmental Fit | Maintains reliability in harsh conditions |

Glass pressing applications often demand precise, localized, and efficient heating. The choice of infrared emitter depends on the specific needs of the process:

Targeted Heating: Some applications require focused heat on small areas, such as edges, rims, or corners. Emitters with high power density and precise control excel in these scenarios.

Rapid Cycling: Processes that need quick on/off cycles benefit from emitters with fast thermal response, ensuring heat is available only when needed.

Automation Compatibility: Modern production lines often integrate automation. Emitters must support seamless communication and control within these systems.

Energy Efficiency: Directing heat only where required reduces energy consumption and operational costs.

Special Environments: Some glass pressing occurs in vacuum or under unique environmental conditions. Emitters must operate reliably in these settings.

YFR addresses these diverse needs with modular and customizable infrared emitter solutions. Their systems offer fast response times and uniform heat distribution, critical for achieving precise shapes and finishes. The modular approach allows customization of emitter type, wavelength, power, and shape, ensuring a tailored fit for each glass pressing application. Round tube lamps and gold reflector options further enhance versatility and efficiency. These features enable manufacturers to optimize process speed, product quality, and energy savings, even in demanding industrial environments.

Proper installation of infrared emitters for glass press applications ensures reliable performance and long service life. Technicians should begin by verifying that all mounting surfaces are clean and free from debris. Secure the emitter modules using the recommended clips or clamps, ensuring firm contact with the designated housing. Position the emitters to provide even coverage across the glass surface, taking care to align the infrared output with the process zone. Connect the control unit and verify all electrical connections meet local safety codes. Before powering on, inspect the system for any visible damage or misalignment.

Tip: Always follow the manufacturer's installation guidelines to prevent premature wear and ensure optimal heat distribution.

A quick setup checklist:

Step | Action |

|---|---|

Mounting | Use approved hardware for secure placement |

Alignment | Direct emitters toward target glass area |

Electrical | Confirm proper wiring and grounding |

Inspection | Check for damage or loose components |

Testing | Run initial power-up and monitor response |

Infrared emitters generate intense heat and radiation, so safety remains a top priority in glass pressing environments. Operators and maintenance staff must use protective eyewear designed to block both infrared and ultraviolet radiation. These glasses or goggles should meet ANSI Z87.1 standards and feature side shields to protect peripheral vision. All personnel in the vicinity must remove reflective objects, such as rings or watches, to prevent hazardous reflections. Only trained and authorized individuals should access the area during operation.

Key safety protocols include:

Wear wavelength-specific protective eyewear at all times.

Restrict access to essential personnel only.

Remove all reflective items from the work area.

Post warning signs indicating infrared hazard zones.

Never look directly at the emitter, even with protection.

Power down or place equipment in standby before adjustments or maintenance.

Operate and maintain equipment only if fully trained.

Avoid using damaged or malfunctioning devices.

Maintain a well-ventilated and secure workspace.

Note: Adhering to these safety measures helps prevent ocular injuries and ensures a safe working environment for everyone involved.

Optimizing the performance of infrared emitters in glass pressing involves both equipment and process adjustments. Engineers should use advanced control systems to deliver consistent and repeatable heat application. Customizing the emitter’s shape, size, and spectrum to match the specific glass pressing requirements can further enhance efficiency. Unique filament designs allow for precise heat targeting, reducing the risk of distortion in finished products.

Operators can maximize uptime by designing systems for minimal maintenance. Collaboration with technical teams enables the creation of flexible heating solutions that adapt to evolving production needs. Adjusting energy density and wavelength ensures optimal heat delivery, supporting high-quality results and energy savings.

Tip: Regularly review process parameters and collaborate with engineers to tailor infrared heating systems for both current and future glass pressing applications.

Proper maintenance ensures that an infrared emitter for glass press delivers consistent performance and a long operational life. Operators should follow a regular care schedule to keep the system running efficiently. Routine care tasks include:

Visual Inspection: Technicians should check the emitter and housing for dust, debris, or discoloration. Clean surfaces help maintain optimal heat transfer.

Cleaning: Use a soft, lint-free cloth to wipe the quartz tube or ceramic surface. Avoid abrasive materials or harsh chemicals. For stubborn residue, apply isopropyl alcohol sparingly.

Connection Check: Inspect all electrical connections and mounting hardware. Tighten any loose screws or terminals to prevent arcing or vibration.

Reflector Maintenance: Examine gold or ceramic reflectors for tarnish or buildup. Clean gently to preserve their reflective properties.

Ventilation: Ensure that cooling fans and air passages remain clear. Blocked airflow can cause overheating and reduce emitter life.

Tip: Schedule maintenance during planned downtime to avoid disrupting production. Document each inspection and cleaning for future reference.

A simple maintenance checklist helps operators stay organized:

Task | Frequency |

|---|---|

Visual Inspection | Weekly |

Cleaning | Bi-weekly |

Connection Check | Monthly |

Reflector Maintenance | Monthly |

Ventilation Check | Monthly |

Even with regular care, issues may arise during the operation of an infrared emitter for glass press. Quick identification and resolution of problems help maintain process stability and product quality. Common issues and solutions include:

Emitter Fails to Heat: Check the power supply and control unit. Replace blown fuses or reset circuit breakers. Inspect the emitter for visible damage.

Uneven Heating: Clean the quartz tube and reflector. Realign the emitter to ensure even coverage. Replace any damaged or discolored components.

Frequent Shutdowns: Verify that cooling fans operate correctly. Remove obstructions from air passages. Ensure that the control system does not detect overheating.

Reduced Output: Inspect for dust or residue on the emitter surface. Clean as needed. Confirm that the power setting matches process requirements.

Electrical Noise or Flicker: Tighten all electrical connections. Replace worn cables or connectors.

Note: Always power down the system and allow components to cool before performing maintenance or troubleshooting.

A troubleshooting table provides quick guidance:

Issue | Possible Cause | Solution |

|---|---|---|

No Heat | Power loss, fuse blown | Check supply, replace fuse |

Uneven Heating | Dirty tube, misalignment | Clean, realign emitter |

Frequent Shutdown | Overheating, blocked air | Clear vents, check fans |

Reduced Output | Surface residue | Clean emitter, check settings |

Electrical Flicker | Loose connection | Tighten or replace connections |

Routine care and prompt troubleshooting keep the infrared emitter for glass press operating at peak efficiency. These practices support consistent product quality and extend the service life of the equipment.

Choosing the right infrared emitter for glass pressing ensures efficient heating, consistent product quality, and reliable process control. Manufacturers benefit from rapid thermal response, energy savings, and advanced customization. Those interested in industrial glass heating solutions can take the following steps:

Review detailed application information, focusing on annealing and glass tempering.

Assess process needs and match lamp wavelength to material requirements.

Utilize customization, technical support, and after-sales service.

Explore product pages, news, and technical documentation.

Contact the provider directly for expert guidance and tailored solutions.

An infrared emitter for glass press is a device that delivers targeted heat to glass during pressing. It uses infrared radiation to achieve precise temperature control, supporting processes like forming, laminating, and coating.

Infrared emitters provide uniform and controlled heating. This reduces defects such as bubbles, cracks, and warping. Consistent heat application ensures high optical clarity and structural integrity in finished glass products.

Medium-wave infrared emitters work best for glass pressing. Glass absorbs this wavelength efficiently, resulting in even heating and reduced energy waste. Gold reflector designs further enhance performance by directing heat precisely.

Yes. YFR offers modular and customizable infrared emitter solutions. Engineers can select emitter type, wavelength, power, and shape to match specific glass pressing requirements, ensuring optimal process results.

Operators should wear protective eyewear, restrict access to essential personnel, and remove reflective items. Warning signs must indicate infrared hazard zones. Only trained staff should operate or maintain the equipment.

Routine maintenance should occur weekly for inspections and bi-weekly for cleaning. Monthly checks for connections, reflectors, and ventilation help ensure reliable operation and extend emitter lifespan.

YFR infrared emitters integrate seamlessly with automated systems. Intelligent control units support real-time monitoring and adjustment, enabling precise process control and compatibility with modern manufacturing environments.

Infrared emitters offer rapid heating, energy efficiency, and precise temperature control. They improve product quality, reduce operational costs, and support advanced process automation in glass manufacturing.