Author: Site Editor Publish Time: 2025-07-22 Origin: Site

I see the short wave infrared lamp as a critical tool for industrial heating. This technology delivers instant, controlled heat that boosts efficiency in demanding environments. I rely on the short wave infrared lamp for processes that require precise temperature control and rapid response. Many industrial buyers struggle to match lamp specifications to their application needs. I focus on practical solutions that help ensure the best fit for every process.

Short wave infrared lamps provide instant, precise heat that improves industrial process speed and quality.

These lamps heat materials directly, saving energy and reducing production time compared to other heat sources.

Quartz tungsten filament and LED-based lamps offer different benefits like fast heating or long lifespan to fit various needs.

Short wave infrared lamps excel in applications like paint curing, powder coating, product inspection, and food processing.

Choosing the right lamp involves matching power, wavelength, and size to the specific material and process requirements.

Proper installation, regular maintenance, and safety precautions ensure lamps work efficiently and last longer.

Reliable supplier support and smart controls help maintain performance and reduce downtime in industrial settings.

Future trends include improved energy efficiency, smart integration, and expanding uses in outdoor and specialized industries.

When I select shortwave infrared lamps for industrial use, I focus on their unique ability to deliver fast, direct heat. A short wave infrared lamp emits radiation in the 700 nm to 1400 nm range. These heat lamps operate at extremely high temperatures, often between 1000 °C and 2200 °C. This high temperature allows the lamps to provide almost instant heating. I see this as a major advantage in processes where speed and precision matter.

The science behind these heat lamps fascinates me. As the temperature of the heating elements rises, the emitted radiation shifts to shorter wavelengths. This shift brings the output closer to visible light, which is why these lamps often glow with a reddish hue. The physical principles at work include Kirchhoff's Law, Boltzmann's Law, and Wien's Displacement Law. These laws explain how the intensity and wavelength of the emitted infrared energy change with temperature.

Tip: I always recommend shortwave infrared lamps for applications that need rapid, targeted heating. Their ability to heat solids directly, rather than just warming the air, sets them apart from other heat lamps.

I rely on several key features when evaluating shortwave infrared lamps for industrial projects. These features distinguish them from medium and long wave alternatives and make them ideal for demanding environments.

Instant Heat: Shortwave infrared lamps reach full output almost immediately. I never have to wait for them to warm up, which saves valuable production time.

High Penetration Efficiency: These heat lamps deliver up to 97% penetration efficiency. They transfer energy directly to the material, not the surrounding air.

Superior Temperature Range: With operating temperatures up to 2200 °C, these lamps handle even the toughest industrial tasks.

Energy Efficiency: Shortwave infrared lamps convert a large portion of electrical energy into usable heat. I see radiating efficiencies of about 80%, which reduces energy costs.

Precise Control: I can adjust the output of these heat lamps quickly, allowing for tight process control.

Durability: While the high temperatures can shorten the lifespan of the lamps, I find that quality heating elements and proper maintenance extend their service life.

Here’s a quick comparison of the main features across different types of heat lamps:

Feature | Shortwave Infrared Lamps | Medium Wave Heat Lamps | Long Wave Heat Lamps |

|---|---|---|---|

Wavelength Range | 0.76 to 2 microns | 2 to 4 microns | Above 8 microns |

Operating Temperature | Up to 5000°F or higher | Up to ~1750°F | Lower temperatures |

Heat Intensity | Instant, high-intensity | Gentler, comfortable | Softest, most diffused |

Energy Efficiency | High | Moderate | Lower |

Typical Applications | Industrial drying, powder coating | Space heating, plastics, textiles | Full-room heating |

Equipment Lifespan | Shorter | Longer | Longest |

When I compare shortwave infrared lamps to other heat lamps, I always notice their unmatched speed and efficiency. They excel in industrial settings where rapid, controlled heating is essential. I trust these lamps to deliver reliable performance, especially when paired with robust heating elements and quality manufacturing.

When I evaluate shortwave infrared lamps for industrial use, I always consider the different types available. Each type of heat lamp offers unique benefits and fits specific industrial needs. I have found that understanding these types helps me select the right solution for every process.

I often choose quartz tungsten filament shortwave infrared lamps for their rapid response and high efficiency. These heat lamps reach full power in just 1 to 2 seconds. I see this fast heating as a major advantage in industrial settings where time matters. The lamps operate at temperatures up to 1000℃, which allows them to deliver intense heat quickly. I rely on these types of heat lamps for processes that require deep penetration and uniform heating.

Some key advantages I have observed include:

Fast heating that penetrates the object surface and heats from the inside out, which prevents surface sealing and blistering.

Energy savings, since matching the infrared wavelength to the material leads to better absorption and lower energy use.

Precise temperature control, often within ±1℃, especially when I use SCR regulators.

Clean operation, as these lamps use electricity and produce no harmful emissions.

Flexible installation, with options like gold or ceramic reflectors to boost efficiency.

However, I have noticed that these types of heat lamps can cause uneven heating on objects with irregular shapes. Sometimes, I need to add hot air to achieve uniform results. Despite this, I find quartz tungsten filament shortwave infrared lamps cost-effective due to their long lifespan and high working temperature.

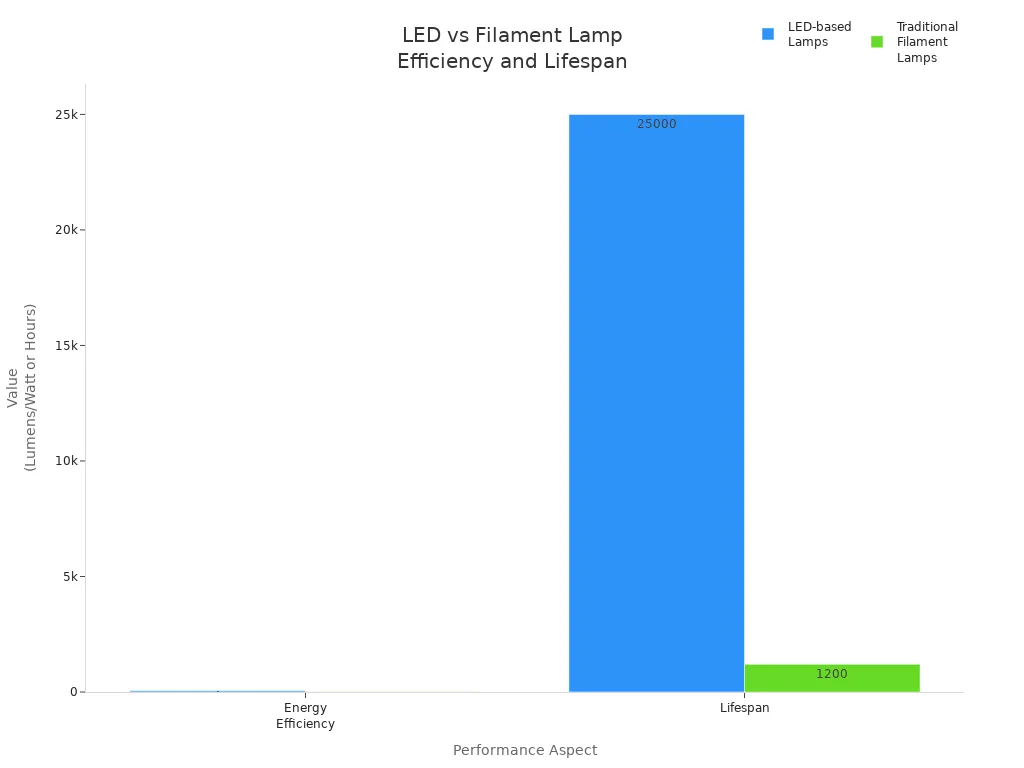

I have seen LED-based shortwave infrared lamps become more popular in recent years. These types of heat lamps stand out for their energy efficiency and long lifespan. When I compare them to traditional filament heat lamps, the difference is clear. LED-based lamps use up to 85% less energy, which lowers electricity costs and supports environmental goals. I also appreciate that these lamps last much longer, reducing the need for frequent replacements.

Here is a comparison I often use:

Aspect | LED-based Lamps | Traditional Filament Lamps (Incandescent) |

|---|---|---|

Energy Efficiency | 37-120 lumens/watt (system >50) | ~10 lumens/watt; ~90% energy lost as heat |

Lifespan | 25,000 to 200,000+ hours | ~1,200 hours |

Failure Mode | Gradual dimming; partial failure | Abrupt hard failure |

Maintenance & Costs | Higher upfront, lower lifetime/maintenance | Low upfront, high maintenance/replacement |

I recommend LED-based shortwave infrared lamps for applications where energy savings and low maintenance are priorities. These types of heat lamps also provide reliable performance over time, making them a smart investment.

In my experience, specialty types of shortwave infrared lamps serve niche industrial applications. I have used several types of heat lamps designed for specific tasks, such as:

Quartz tungsten infrared lamps for high efficiency and rapid heating.

Carbon infrared lamps, which operate at lower temperatures and offer precise control, ideal for medical and food processing.

Halogen infrared lamps, which deliver intense, focused heat and work well for automotive paint curing.

Short wave quartz lamps and ruby lamps for precision heating and sterilization.

Twin tube infrared heaters for large-scale drying and curing.

These specialty types of heat lamps help me address unique challenges in industries like automotive, food processing, and healthcare. I value their rapid heating, energy efficiency, and the ability to match wattage and physical specifications to each process. When I need a tailored solution, I turn to these specialty types of shortwave infrared lamps to meet demanding requirements.

I have seen shortwave infrared lamps transform paint curing in automotive and manufacturing environments. These heat lamps deliver concentrated heating that accelerates drying times. I can move them easily and position them for optimal coverage, which ensures even results on complex surfaces. With rapid heating, I reduce cycle times and boost productivity. I also notice that these lamps offer high energy efficiency, sometimes saving up to 35% on energy costs. The ability to adjust settings and use accessories makes them versatile for different spray booths and preparation areas.

Note: Shortwave infrared lamps help me achieve a flawless finish by preventing surface imperfections and enhancing color accuracy. I rely on their portability and flexibility to adapt to various production needs.

When I use these lamps, I see improved paint quality and reduced operating costs. The targeted heating ensures that every layer cures evenly, which minimizes rework and waste.

Shortwave infrared lamps have become my preferred choice for powder coating lines. These heat lamps provide direct infrared heating, which means I do not waste energy warming the surrounding air. This approach leads to faster heating and significant energy savings—sometimes over 50% compared to conventional ovens. I appreciate that there is no warm-up time, so I can start the process immediately and maintain high throughput.

Here is a comparison of powder coating with shortwave infrared lamps versus conventional heating:

Aspect | Shortwave Infrared Lamps | Conventional Heating |

|---|---|---|

Curing Time | 30–120 seconds | 15–20 minutes |

Heating Mechanism | Direct penetration of coating and substrate | Convection or conduction |

Energy Efficiency | Targeted, minimal heat loss | More heat lost to environment |

Coating Quality | Better adhesion, gloss, and smoothness | Higher risk of defects |

Productivity | Increased due to rapid heating | Lower throughput |

I find that precise temperature control allows me to achieve uniform results, even with sensitive coatings. The compact design of these systems fits easily into my production line. I also value the clean operation, as there are no open flames or emissions. The result is a brilliant, durable finish with improved adhesion and minimal defects.

I use shortwave infrared lamps to enhance product inspection accuracy and speed. These lamps support advanced imaging systems that combine visible and infrared wavelengths. With this technology, I can detect contaminants, inspect contents in opaque packaging, and sort materials more efficiently. The integration of broad-spectrum imaging reduces the need for multiple cameras and lowers system costs.

Shortwave infrared lamps also play a key role in several inspection-related tasks:

Component testing: I achieve precise and uniform thermal control, which speeds up reliability checks.

Paint curing and drying: Even, rapid heating ensures consistent finishes and reduces the need for re-inspection.

Plastic welding: Targeted heating improves precision and reduces errors.

Adhesive drying: Controlled heating shortens assembly times and ensures strong bonds.

Surface cleaning: Rapid heating removes contaminants, preparing surfaces for accurate inspection.

I have found that these lamps make inspection processes faster and more reliable. The detailed imaging and uniform heating help me maintain high quality standards across my operations.

I have seen short wave infrared lamps revolutionize identification and sorting in industrial environments. These lamps, especially those using tungsten-halogen, LED, or laser diode technology, emit radiation in the short wave infrared region. This radiation interacts with materials through transmission, reflection, absorption, and scattering. I rely on these interactions for rapid, non-destructive analysis of materials. The ability to penetrate packaging and inspect internal features sets this technology apart.

I use SWIR lamps for food sorting, where they detect moisture, bruises, and defects in fruits and vegetables.

In recycling and manufacturing, I sort materials by identifying their unique spectral signatures.

For quality control, I inspect polymers and plastics, ensuring consistency and detecting contaminants.

Semiconductor inspection becomes more precise, as SWIR imaging reveals hidden defects and internal structures.

SWIR imaging operates in the 900 nm to 1700 nm range. I find this range ideal for penetrating materials like silicon, plastics, and fabrics. The technology supports real-time monitoring and quality control. I can synchronize the lamps with detectors and optical systems, allowing targeted inspection and rapid sorting. Minimal sample preparation and the ability to integrate into existing processes make SWIR lamps a practical choice. I value the speed and accuracy they bring to identification and sorting tasks.

I have used short wave infrared lamp technology to enhance anti-counterfeiting measures across several industries. By incorporating luminescent materials such as rare-earth ion doped nanoparticles into tags, labels, or packaging, I create unique optical patterns that only reveal their encoded information when excited by SWIR lamps. These patterns, including barcodes or QR codes, possess distinct spectral fingerprints and long decay times. This makes them extremely difficult to replicate. I rely on advanced authentication methods like time-gated and lifetime imaging to verify genuine products. The ability to embed these materials into inks or polymers allows me to scale up protection for banking, pharmaceuticals, electronics, and packaging. The stability and high performance of these luminescent materials ensure robust security against counterfeiting.

I have found short wave infrared lamps indispensable in food processing. Their direct and efficient heating transforms how I dry, bake, and sterilize food products. The following table summarizes the main benefits I experience when using this technology:

Benefit | Explanation |

|---|---|

High energy efficiency | IR lamps convert electricity directly into heat with low energy consumption and high thermal efficiency. |

Fast and uniform heating | IR radiation heats food quickly and evenly, reducing processing time and improving product consistency. |

Improved product quality | IR heating preserves aroma, reduces chemical decomposition, and maintains organoleptic qualities. |

Microbial inactivation | Non-contact IR sterilization effectively inactivates microbes without chemicals, enhancing food safety. |

Environmental friendliness | IR heating does not require water or heating liquids, produces no harmful emissions, and saves resources. |

Precise process control | Compact IR equipment allows accurate control of temperature and heating parameters. |

Versatility in applications | Used in drying, baking, sterilization, and combined with other methods (microwave, vacuum) to improve efficiency. |

Non-contact heating | Reduces contamination risk and improves hygiene during food processing. |

Effective penetration | IR radiation penetrates food surfaces, converting radiation into heat, enhancing drying rates and energy savings. |

Reduced drying time and energy | Combined IR and convective drying reduced drying time by 48% and energy consumption by 63% in vegetables. |

I appreciate how this technology allows me to maintain high hygiene standards. The non-contact heating reduces contamination risk. I also achieve faster processing and better product quality. The versatility of short wave infrared lamps supports a wide range of food industry applications, from drying grains to sterilizing herbal medicines.

I have seen short wave infrared lamps become essential in electronics manufacturing. These lamps provide rapid, precise heating that supports a wide range of processes, from soldering to coating and drying. I rely on their fast response to keep production lines moving efficiently. When I work with sensitive electronic components, I need a solution that delivers heat quickly without causing damage. Short wave infrared lamps meet this need with their non-contact approach.

I use these lamps for soldering printed circuit boards (PCBs), drying protective coatings, and bonding delicate materials. The ability to control temperature accurately ensures that each solder joint forms correctly. I avoid common defects like voids and cracks, which can compromise reliability. The uniform heating also reduces thermal stress, preventing microcracks and extending the lifespan of electronic products.

Here is a summary of how short wave infrared lamps contribute to efficiency and quality in electronics manufacturing:

Feature | Contribution to Electronics Manufacturing Efficiency and Quality |

|---|---|

Fast Heating | Enables rapid and uniform heating of coatings, reducing processing time and improving production speed. |

Energy Saving | Reduces energy consumption due to quick heating, lowering production costs and environmental impact. |

Accurate Temperature Control | Ensures uniform drying and solidification of coatings, enhancing coating quality and product reliability. |

Environmental Protection | Generates less exhaust and waste compared to traditional methods, supporting cleaner manufacturing processes. |

I have found that non-contact heating is especially valuable when working with fragile solar wafers or microchips. The lamps prevent mechanical damage and contamination, which helps maintain a clean production environment. I also appreciate the high temperature capability. These lamps can reach temperatures above 1000°C, making them suitable for a variety of materials and component sizes.

The following table highlights additional process features that improve efficiency and quality:

Process Feature | Contribution to Efficiency and Quality in Electronics Manufacturing |

|---|---|

Precise and Uniform Heating | Ensures controlled temperature during soldering, improving joint quality and reliability. |

Non-contact Heating | Avoids mechanical damage to delicate solar wafers, preserving component integrity. |

Thermal Stress Reduction | Uniform heating prevents microcracks and efficiency loss, enhancing product lifespan. |

Rapid Heating and Stability | Enables complete solder melting without overheating, optimizing process efficiency. |

Tip: I always monitor temperature closely during electronics manufacturing. This practice ensures that each heating cycle delivers consistent results and maintains high product quality.

I have seen production lines benefit from reduced soldering duration and improved solder joint quality. The fast response of short wave infrared lamps allows for rapid process cycles and uniform heating, which increases productivity and reduces costs. I trust this technology to deliver reliable, high-quality results in every electronics manufacturing project.

When I select shortwave infrared lamps for industrial applications, I always start by evaluating the power rating. The power rating determines how much heat the lamp can deliver and how quickly it can reach the desired temperature. I have seen that higher power ratings allow these lamps to achieve heating speeds up to ten times faster than traditional methods. For example, in PVC sheet thermoforming, I reduced the cycle time from 120 seconds to just 20 seconds by choosing a lamp with the right power density.

I look for lamps that offer precise temperature control, often within ±1°C. This level of control prevents overheating and protects sensitive materials from damage. I also consider the power density, which can reach up to 300KW/m² in some models. This flexibility lets me tailor the lamp’s performance to specific processes, such as plastic welding, bonding, or medical device manufacturing.

Tip: I always match the lamp’s power rating to the process requirements. Too much power can damage materials, while too little power leads to slow production and uneven results.

Shortwave infrared lamps with adjustable power ratings give me the ability to fine-tune the heating process. I can optimize cycle times, improve product quality, and reduce defect rates by selecting the right lamp for each application.

Wavelength selection plays a critical role in the effectiveness of shortwave infrared lamps. I know that different materials absorb infrared radiation at different wavelengths. To maximize heating efficiency, I always match the lamp’s emission wavelength to the absorption spectrum of the material I am working with.

Shortwave infrared lamps operate at higher temperatures and emit shorter wavelengths, which provide high power density and rapid response. This makes them ideal for fast heating applications, such as rapid drying or curing. However, if the wavelength does not align with the material’s absorption characteristics, the process becomes less efficient. For instance, water-based inks absorb infrared best at medium and long wavelengths, so I avoid using shortwave infrared lamps for those materials to prevent overheating.

I use the following table to guide my wavelength selection:

Material Type | Best Absorbed Wavelength | Recommended Lamp Type |

|---|---|---|

Metals | Shortwave (0.76–2 µm) | Shortwave infrared lamps |

Plastics/Polymers | Medium/Longwave (2–4 µm) | Medium/longwave infrared lamps |

Water-based Coatings | Medium/Longwave (3–4.5 µm) | Medium/longwave infrared lamps |

Glass | Shortwave (0.76–2 µm) | Shortwave infrared lamps |

By carefully matching the wavelength to the application, I achieve efficient heat transfer, protect sensitive materials, and ensure optimal process outcomes. I always consult the absorption characteristics of the target material before making a final decision.

Lamp length is another important factor I consider when choosing shortwave infrared lamps. The length of the lamp must match the size and shape of the area I need to heat. If the lamp is too short, it will not provide uniform coverage, leading to cold spots and inconsistent results. If the lamp is too long, it may waste energy and increase operating costs.

I measure the dimensions of the target area and select a lamp length that ensures even heat distribution. For conveyor systems or large drying tunnels, I often use multiple lamps arranged in series to cover the entire width. In smaller or more focused applications, a single lamp with the correct length provides precise, targeted heating.

I also pay attention to the mounting and integration of the lamps. Proper alignment and spacing are essential for achieving uniform results. I work closely with suppliers to customize lamp lengths and configurations for each project.

Note: I always verify that the lamp length fits the installation space and matches the process requirements. This step helps me avoid costly adjustments and ensures efficient operation.

By considering power rating, wavelength, and lamp length, I can select shortwave infrared lamps that deliver energy efficient heating, precise temperature control, and reliable performance for any industrial process. I also make sure to choose lamps with high-quality heating elements to maximize durability and efficiency.

When I select short wave infrared lamps for industrial systems, I always check voltage compatibility first. This step prevents equipment damage and ensures efficient operation. I have seen ultra-short wave infrared lamps create current peaks up to 16 times the nominal current. These peaks can stress power controllers and thyristors if not sized correctly. I never overlook this risk.

I consider the wiring configuration in every installation. Different setups—single phase, delta/star without neutral, star with neutral, or open delta—require specific power controllers. I use specialized controllers like the REVO S, REVEX, or REVO C from CD Automation. These controllers handle the unique current characteristics of these lamps and provide precise power control.

Operating lamps at voltages below their nominal value reduces peak current. However, I have learned that this can cause prolonged overcurrent, which still stresses the thyristors. In automotive applications, I sometimes use low voltage supply to adjust infrared penetration. This approach demands extra care in sizing the thyristors because the overcurrent lasts longer, even if the peak is lower.

I always match the lamp voltage to the system and select the right controller. This practice extends lamp life and maintains reliable performance. I recommend consulting with suppliers to confirm compatibility before installation.

Tip: Never underestimate the importance of voltage compatibility. Proper matching protects your lamps and keeps your process running smoothly.

I always start with a clear understanding of my application needs before choosing lamps. Each industrial process has unique requirements. I look at the material type, heating area, and desired temperature profile. For example, I use different lamps for drying, curing, or bonding. The process speed and product geometry also influence my choice.

I ask myself these questions:

What material am I heating?

How large is the area?

What temperature do I need to reach?

How quickly must the process run?

Is uniform heating critical?

I select lamps that match these needs. For large conveyor systems, I use multiple lamps in series. For precision tasks, I choose lamps with focused output and tight control. I always check if the lamp can integrate with my existing equipment. This step avoids costly modifications later.

I also consider the environment. Dust, humidity, and vibration can affect lamp performance. I choose lamps with protective features for harsh conditions. I work with suppliers to customize solutions when standard options do not fit.

Efficiency remains a top priority in every project. I want lamps that convert as much electrical energy as possible into usable heat. High efficiency lowers operating costs and reduces environmental impact. I look for lamps with radiating efficiencies around 80%. These models deliver more heat to the product and waste less energy.

I compare different lamp types and technologies. Quartz tungsten filament lamps offer fast response and high output. LED-based lamps provide even greater energy savings and longer life. I select the type that best fits my process and budget.

I monitor system efficiency over time. I check for signs of energy loss, such as uneven heating or excessive power draw. Regular maintenance keeps my lamps performing at their best. I also upgrade to newer, more efficient models when possible.

Note: Efficient lamps not only save money but also support sustainability goals. I always factor efficiency into my selection process.

When I evaluate short wave infrared lamps for industrial use, I always prioritize durability. Industrial environments often expose equipment to harsh conditions, so I need lamps that can withstand demanding applications. I look for features and design elements that extend the service life and maintain consistent performance.

High penetration power allows these lamps to cure thicker coatings effectively. This capability ensures that coatings last longer, even in tough environments.

Rapid temperature rise reduces curing times. Faster processes mean less thermal stress on the lamp, which helps preserve its lifespan.

Controlled and consistent curing supports the durability of both the lamp and the finished product. I see this as essential in sectors like marine and aerospace, where coatings must endure extreme conditions.

The demand for high-performance coatings in industries exposed to harsh environments drives the use of robust short wave infrared lamps.

Ongoing technological advancements improve both performance and energy efficiency. These improvements indirectly enhance the durability and reliability of the lamps in demanding settings.

I always select lamps constructed from high-quality materials such as stainless steel, aluminum, or carbon steel. A stable base and protective covers prevent damage from impacts or oxidation. I also check for smart features like adjustable operation and built-in timers, which reduce unnecessary wear and extend the lamp’s service life.

Tip: I recommend regular maintenance and inspection. Cleaning the lamp surface and checking for signs of wear help prevent unexpected failures and maximize durability.

I have learned that supplier support plays a critical role in the long-term performance and reliability of short wave infrared lamp installations. Reliable suppliers, such as Lumileds, invest in rigorous reliability testing programs. These programs identify and address potential failures early in the product design cycle. Accelerated reliability, environmental stress, and mechanical tests ensure that each lamp meets strict industry standards. I value suppliers who maintain accredited labs to assess lumen maintenance and failure modes. This approach reduces abrupt failures and ensures predictable, long-term performance.

When I choose a supplier, I look for the following support features:

Feature Category | Description |

|---|---|

Easy Installation | Lamp includes all parts and user manual; assembly requires only four simple steps, enabling quick setup and immediate use. |

Durable Construction | Made from stainless steel, aluminum, and carbon steel; stable base and materials ensure long lifespan and reliability. |

Safety Design | High-quality halogen tubes, anti-oxidation stainless steel cover, thickened base for stability, smooth edges to prevent injury. |

Adjustable Operation | Height and angle adjustable; 60-minute smart timer; mobility via lockable casters; allows customization for optimal performance. |

Long Lifespan | Emitter rated for 6000 hours, supporting sustained use without frequent replacements. |

I always consult with suppliers about installation, maintenance, and replacement parts. Strong supplier support minimizes downtime and ensures that my lamps deliver consistent results over time. I trust suppliers who provide clear documentation, responsive technical assistance, and ongoing product improvements.

Note: Choosing a supplier with comprehensive support services protects my investment and keeps my operations running smoothly.

I always start every installation by preparing the workspace and gathering the right tools. I clear the area of any debris or obstacles. This step prevents accidents and ensures smooth movement during setup. I check the lamp packaging for damage. If I see any cracks or broken parts, I contact the supplier before proceeding.

I lay out all components and review the installation manual. I find that reading the manual first saves time and reduces mistakes. I wear protective gloves and safety glasses. These items protect me from sharp edges and accidental contact with the lamp surface.

Here is my basic preparation checklist:

Inspect all lamp components for damage

Read the installation manual thoroughly

Wear appropriate personal protective equipment (PPE)

Prepare mounting hardware and tools

Ensure the workspace is clean and well-lit

Tip: I always keep a fire extinguisher nearby. Safety comes first in every installation.

I pay close attention to the electrical setup. I verify the voltage and current requirements for the lamp. I match these values to the facility’s power supply. Incorrect voltage can damage the lamp or cause poor performance.

I use a certified electrician for wiring. This step ensures compliance with local codes and prevents electrical hazards. I connect the lamp to a dedicated circuit. This practice avoids overloads and keeps the lamp running reliably.

I follow these steps for a safe electrical setup:

Turn off the main power supply before starting any wiring.

Confirm the lamp’s voltage and current ratings.

Use the correct gauge of wire for the lamp’s power draw.

Install a circuit breaker or fuse for added protection.

Connect the lamp to the power source using secure terminals.

Double-check all connections before restoring power.

Note: I never skip grounding the lamp. Proper grounding protects both equipment and personnel from electrical faults.

I focus on seamless integration with existing systems. I align the lamp with the process line or target area. I adjust the mounting brackets for stability and optimal heat coverage. I check that the lamp does not interfere with other equipment.

I connect the lamp’s control system to the main process controller. This connection allows me to automate heating cycles and monitor performance. I test the lamp at low power first. This step helps me identify any issues before full operation.

Here is a quick integration checklist:

Align lamp with process flow

Secure all mounting points

Connect control systems for automation

Test lamp at low power

Monitor for abnormal noise or heat

Reminder: I document every step of the installation. Good records help with future maintenance and troubleshooting.

I always make routine care a top priority for my short wave infrared lamps. Regular maintenance keeps my equipment running efficiently and extends its lifespan. I follow a simple checklist to ensure each lamp stays in peak condition:

Clean the lamp surface: I use a soft, lint-free cloth to wipe away dust and debris. I avoid harsh chemicals that could damage the quartz or protective coatings.

Inspect for signs of wear: I look for discoloration, cracks, or cloudiness on the lamp tube. These issues can signal overheating or aging.

Check electrical connections: I tighten any loose terminals and examine wires for fraying or corrosion.

Monitor operating temperature: I use an infrared thermometer to confirm the lamp heats evenly. Uneven temperatures may indicate a failing element.

Test safety features: I verify that timers, thermal cutoffs, and protective covers work as intended.

Tip: I schedule routine care every month in high-use environments. For less demanding applications, quarterly checks often suffice.

When a lamp fails to perform as expected, I rely on a systematic troubleshooting approach. I start with the most common issues and work my way through possible causes. Here is a table I use to guide my process:

Symptom | Possible Cause | Solution |

|---|---|---|

Lamp does not turn on | Blown fuse, faulty wiring | Replace fuse, check connections |

Flickering or dim light | Loose terminal, aging lamp | Tighten terminals, replace lamp |

Uneven heating | Dirty surface, element fault | Clean lamp, inspect element |

Overheating | Blocked airflow, wrong voltage | Clear vents, verify voltage |

Short lifespan | Frequent cycling, vibration | Reduce cycles, secure mounting |

I always isolate the lamp from power before inspecting or repairing it. Safety comes first. If I cannot resolve the issue quickly, I consult the supplier’s technical support for expert guidance.

Note: I document every troubleshooting step. Good records help me spot recurring problems and improve future maintenance.

Eventually, every lamp reaches the end of its service life. I watch for signs like persistent dimming, slow warm-up, or visible damage. When replacement becomes necessary, I follow these steps:

Power off and cool the lamp completely.

Remove the old lamp using insulated gloves.

Clean the mounting area to remove dust and debris.

Install the new lamp, ensuring proper alignment and secure connections.

Test the lamp at low power before returning to full operation.

I always use genuine replacement parts from trusted suppliers. This practice ensures compatibility and maintains system performance. I keep spare lamps in stock to minimize downtime.

Reminder: Proper disposal of old lamps matters. I follow local regulations for recycling or hazardous waste to protect the environment.

When I handle short wave infrared lamps in industrial settings, I always treat them with respect. These lamps operate at high voltages, which means I disconnect the power before any maintenance or replacement. I never touch the lamp surface while it is hot. The glass can reach extreme temperatures and cause serious burns. I wait until the lamp cools completely before handling it.

I also stay alert to the risk of explosion. Some lamps contain high internal pressure. I avoid dropping or striking them, and I use a face shield or safety glasses during installation or removal. I never dispose of a lamp without first relieving internal pressure. Incineration is not safe for these products.

Here are the most common risks I watch for:

Electrical shock from high ignition voltage

Severe burns from hot lamp surfaces

Eye and skin damage from direct or reflected UV, visible, or IR radiation

Ozone emissions that can cause breathing problems if ventilation is poor

Fire hazards if lamps are near flammable materials

Explosion risk from high-pressure lamps

Improper disposal leading to environmental or safety issues

Tip: I always follow manufacturer instructions and use proper fixtures to reduce risks.

I never work with short wave infrared lamps without the right protective equipment. I wear insulated gloves to prevent burns and electrical shock. Safety glasses or a face shield protect my eyes from accidental exposure to intense light or flying glass if a lamp breaks. In areas with poor ventilation, I use a respirator to avoid inhaling ozone.

I make sure my clothing covers my arms and legs. This simple step protects my skin from accidental exposure to radiation. I also keep a fire extinguisher nearby in case of emergencies. These safety measures help me avoid injuries and keep my team safe.

I always check that my installation and operation practices meet local and international safety standards. I follow OSHA guidelines for electrical safety and personal protective equipment. I also comply with manufacturer recommendations for lamp handling, installation, and disposal.

Proper labeling and warning signs remind everyone in the area about potential hazards. I train my team on safe operating procedures and emergency response. Regular safety audits help me identify risks and improve our safety measures.

Remember: Consistent compliance with regulations and best practices protects both people and equipment.

I have seen outdoor infrared heaters become essential in many industrial environments. I use these heaters to maintain productivity in loading docks, warehouses, and outdoor assembly lines. When I need to keep workers comfortable during cold weather, I rely on outdoor infrared heaters to deliver targeted warmth. These heaters work well in open-air workstations, construction sites, and even outdoor storage areas where traditional heating fails.

I often install outdoor infrared heaters in areas where wind and weather make other heating methods ineffective. The radiant heat from these units warms people and objects directly, not the air. This feature allows me to maintain a stable temperature for sensitive materials or equipment, even in exposed locations. I also use outdoor infrared heaters for temporary workspaces, such as tents or mobile repair stations. Their portability and quick setup save me time and effort.

Tip: I always choose outdoor infrared heaters with weather-resistant housings and safety certifications. This ensures reliable performance in harsh conditions.

When I compare outdoor infrared heaters to indoor systems, I notice several important differences. Outdoor infrared heaters must withstand rain, dust, and temperature swings. I select models with sealed enclosures and corrosion-resistant materials for these environments. Indoor systems, on the other hand, focus more on aesthetics and integration with building controls.

Here is a table that summarizes the key differences I consider:

Feature | Outdoor Infrared Heaters | Indoor Infrared Heaters |

|---|---|---|

Weather Resistance | High (IP-rated, sealed) | Low to moderate |

Installation Location | Exposed, open-air, semi-enclosed | Enclosed, climate-controlled |

Heat Distribution | Direct, focused on people/objects | Broader, ambient |

Durability | Enhanced for outdoor use | Standard |

Maintenance Needs | More frequent (due to elements) | Less frequent |

I find that outdoor infrared heaters require more frequent inspection and cleaning. Dust, moisture, and debris can affect performance. I always schedule regular maintenance to keep these heaters running efficiently. Indoor systems usually need less attention, but I still check them for dust buildup and electrical issues.

I recommend evaluating the specific needs of your workspace before choosing between outdoor infrared heaters and indoor systems. The right choice depends on exposure, durability, and heating goals.

I see efficiency improvements shaping the future of short wave infrared lamps. Manufacturers now focus on reducing energy consumption and carbon footprints. I notice that government regulations push companies to innovate. Research and development investments lead to better lamp designs and rapid heating capabilities. I often choose lamps that offer real-time monitoring and energy optimization. These features help me cut costs and improve productivity.

Many industries, such as automotive and food processing, benefit from faster drying and curing times.

I find that medium power lamps, ranging from 1,000 to 3,000 watts, strike a balance between power and efficiency.

Customization for specific industrial processes allows me to tailor heating solutions for unique needs.

I see more companies integrating short wave infrared lamps with renewable energy sources, like solar, to create eco-friendly systems.

The rapid heating capability supports faster production cycles, which is crucial in competitive markets.

I expect the global market for these lamps to grow as more sectors adopt efficient heating solutions. I also see outdoor infrared heaters adopting these innovations, making them more energy efficient and environmentally friendly.

Smart integration stands out as a major trend in industrial heating. I now use lamps that connect with automation systems and smart controls. These systems let me monitor performance and adjust settings in real time. I can track energy use, detect faults, and schedule maintenance from a central dashboard. This level of control helps me prevent downtime and extend lamp life.

I see outdoor infrared heaters benefiting from smart integration as well. I can program these heaters to respond to weather changes or occupancy levels. This approach ensures that I only use energy when and where I need it. I also notice that smart sensors and IoT connectivity make it easier to manage large installations across multiple sites.

Smart integration not only boosts efficiency but also supports predictive maintenance. I can address issues before they cause failures, saving time and money.

I watch new applications for short wave infrared lamps emerge every year. I see outdoor infrared heaters used in more diverse environments, from construction sites to outdoor event spaces. These heaters now support tasks like drying coatings on bridges or curing materials in open-air factories. I also use outdoor infrared heaters for temporary shelters and emergency response setups.

In healthcare, I see these lamps used for sterilization and rapid drying of medical equipment. The food industry now relies on them for precise baking and drying processes. I expect outdoor infrared heaters to play a bigger role in agriculture, helping with crop drying and pest control in the field.

I believe that as technology advances, outdoor infrared heaters will become even more versatile. I look forward to using them in new ways that improve efficiency, safety, and sustainability across industries.

When I choose a short wave infrared lamp, I focus on power rating, wavelength, lamp length, and voltage compatibility. I always match these features to my specific industrial process. Reliable supplier support and efficiency matter to me. I recommend reviewing your current systems and consulting trusted suppliers for expert advice.

Stay informed about new technologies to keep your operations efficient and competitive.

I usually see lifespans between 5,000 and 7,000 hours for quartz tungsten filament lamps. LED-based models last much longer, often exceeding 25,000 hours. Proper maintenance extends service life.

Yes, I use these lamps in both settings. For outdoor use, I select models with weather-resistant housings and proper safety certifications. I always check the IP rating before installation.

I match the lamp’s wavelength to the material’s absorption spectrum. Metals absorb shortwave best. Plastics and water-based coatings need medium or longwave. I consult supplier charts or request sample testing for confirmation.

I find these lamps highly efficient. They convert up to 80% of electrical energy into usable heat. LED-based models offer even greater efficiency and lower operating costs.

I always disconnect power before handling lamps. I wear insulated gloves and safety glasses. I avoid touching the lamp surface. I follow manufacturer instructions and use proper mounting hardware.

I schedule monthly inspections in high-use environments. For less demanding applications, quarterly checks work well. I clean lamp surfaces, check connections, and monitor performance during each session.

Yes, I use compatible power controllers or SCR regulators to adjust output. This allows me to fine-tune heating for different processes and improve energy savings.

I check for installation errors, voltage mismatches, or poor ventilation. I consult the supplier for troubleshooting support. I always use genuine replacement parts to avoid repeat failures.