Views: 0 Author: Site Editor Publish Time: 2025-08-04 Origin: Site

Automotive, electronics, and food processing industries lead the adoption of infrared heater bulb technology in 2025 due to their demand for efficiency and consistent quality. YFR, a trusted American manufacturer with 14 years of expertise, delivers advanced quartz infrared lamps and drying systems that support these sectors. Companies report measurable improvements such as reduced cycle times, energy savings, and enhanced product quality.

Industry | Key Benefits | Performance Metrics |

|---|---|---|

Automotive | Faster paint drying, improved durability | Shorter cycles, fewer defects, lower maintenance costs |

Electronics | Rapid processing, energy efficiency | 15-30% faster cycles, up to 50% less energy use |

Food & Beverage | Even cooking, better hygiene | Uniform browning, extended shelf life |

Infrared heater bulbs provide fast, direct heat that improves efficiency and product quality across many industries.

These bulbs save energy by heating objects directly, reducing waste and lowering operational costs by up to 50%.

Smart controls and automation allow precise temperature management, boosting productivity and reducing errors.

Customization options let manufacturers tailor infrared bulbs to specific processes, materials, and environments.

Infrared heating supports sustainability by cutting emissions, conserving water, and reducing waste in production.

Industries like automotive, food processing, medical, electronics, plastics, aerospace, chemical, mining, printing, and comfort heating benefit from this technology.

American-made infrared heater bulbs, such as those from YFR, offer reliable quality, fast delivery, and strong supply chain resilience.

Infrared heater bulbs enhance workplace safety with features like shatter resistance, automatic shutoff, and no open flames.

An infrared heater bulb is a specialized lamp that emits infrared radiation to generate heat. These bulbs convert electrical energy into infrared energy, which directly warms objects and surfaces rather than the surrounding air. This targeted heating method increases efficiency and reduces energy waste. Industries use infrared heater bulbs for tasks that require precise, rapid, and uniform heating. The technology supports applications ranging from industrial drying to food preparation and medical equipment sterilization.

Infrared heater bulbs come in several types, each designed for specific applications and performance needs. The main types available in 2025 include:

Carbon Heating Lamps: Known for fast response times and high efficiency, these lamps suit high-temperature material processing.

Ruby Heat Lamps: These bulbs feature a red-tinted glass that filters visible light, making them ideal for textile printing and leather curing.

Gold Infrared Lamps: With a gold coating, these lamps provide focused heat and are often used for spot heating and seafood drying.

Quartz Glass Tube Lamps: Durable and versatile, quartz lamps handle a wide range of industrial heating tasks.

Graphene IR Heat Lamps: These advanced lamps offer improved energy efficiency and longer lifespans, supporting sustainable operations.

Special Shaped Heat Lamps: Custom shapes and power ratings allow these bulbs to meet unique industrial requirements.

Infrared heaters also fall into two main categories: high intensity and low intensity. High intensity units, often gas-fired, operate at temperatures above 1350°F and deliver concentrated infrared radiation. These are common in large-scale space heating and outdoor environments. Low intensity heaters serve different operational needs, providing gentler heat for more sensitive applications.

Infrared heater bulbs offer several advantages that drive their adoption across industries:

Energy Efficiency: Direct heating of objects and surfaces reduces energy loss, lowering operational costs.

Rapid Heating: Infrared bulbs reach target temperatures quickly, improving process speed and productivity.

Consistent Results: Uniform heat distribution ensures product quality and reduces defects.

Versatility: Customizable shapes, wattages, and voltages allow these bulbs to fit diverse industrial and commercial needs.

Enhanced Safety: Modern designs include shatter-resistant bulbs and reduced burn risks, supporting safer workplaces.

Note: The growing popularity of infrared heater bulbs in 2025 stems from rising energy costs, stricter environmental regulations, and the integration of smart technology. Industries seek sustainable, efficient, and reliable heating solutions, making these bulbs a preferred choice.

The year 2025 marks a pivotal moment for the infrared heater bulb industry. Several trends drive the rapid adoption of this technology across multiple sectors. Companies seek solutions that deliver efficiency, sustainability, and adaptability. The following trends define the landscape for infrared heating in 2025:

Smart Integration: Manufacturers now design infrared heater bulbs with smart controls. These systems connect to industrial automation platforms and building management systems. Operators can monitor and adjust heating parameters remotely. This integration leads to precise temperature control and reduced energy consumption.

Sustainability Initiatives: Environmental regulations continue to tighten. Businesses look for ways to lower their carbon footprint. Infrared heater bulbs support these goals by offering direct, targeted heating. This approach minimizes wasted energy and reduces greenhouse gas emissions. Many companies now highlight their use of energy-efficient heating in sustainability reports.

Customization and Modularity: Industries demand heating solutions tailored to specific processes. Manufacturers respond by offering modular infrared heater bulb systems. These systems allow for easy upgrades and replacements. Custom shapes, wattages, and voltages ensure compatibility with unique production lines.

Advanced Materials: Research and development teams focus on new materials for infrared heater bulbs. Innovations in quartz, graphene, and specialty coatings extend bulb lifespan and improve efficiency. These advancements also enhance safety and reliability in demanding environments.

Global Supply Chain Resilience: The events of recent years have highlighted the importance of robust supply chains. Companies now prioritize suppliers with domestic manufacturing capabilities. American-made infrared heater bulbs, such as those from YFR, gain preference due to reliable delivery and consistent quality.

Cross-Industry Expansion: Infrared heater bulbs move beyond traditional sectors. New applications emerge in agriculture, textiles, and even renewable energy. For example, greenhouses use infrared heating to optimize plant growth. Textile manufacturers adopt the technology for rapid drying and finishing.

Note: Industry analysts predict continued growth for the infrared heater bulb market through 2030. Adoption rates rise as more businesses recognize the measurable benefits of this technology. Companies that invest in advanced heating solutions position themselves for long-term success.

A table below summarizes the key trends shaping the industry in 2025:

Trend | Impact |

|---|---|

Smart Integration | Improved control, lower energy use |

Sustainability Initiatives | Reduced emissions, regulatory compliance |

Customization & Modularity | Flexible solutions for diverse industries |

Advanced Materials | Longer lifespan, higher efficiency |

Supply Chain Resilience | Reliable sourcing, consistent quality |

Cross-Industry Expansion | New applications, broader market reach |

Manufacturing facilities rely on advanced heating technologies to maintain productivity and product quality. Infrared heater bulbs play a vital role in several core processes, especially drying and curing.

Manufacturers use infrared heater bulbs for rapid and uniform drying of coatings, inks, adhesives, and organic materials. This technology enables contactless heat transfer, which speeds up evaporation and reduces the risk of defects. For example, in paper and textile production, infrared drying penetrates material surfaces, accelerating production and saving energy. Graphic arts businesses benefit from customizable wattages and wavelengths, ensuring inks dry quickly and evenly on various substrates.

Curing processes demand precise temperature control and consistent heat distribution. Infrared heater bulbs deliver targeted energy, making them ideal for powder coating, paint curing, and plastics processing. In powder coating, even heat distribution results in polished, smooth surfaces. Plastics manufacturers use infrared heating to prepare bioplastics for thermoforming, ensuring packaging meets strict quality standards. The semiconductor industry also relies on this technology for controlled temperature environments during manufacturing.

YFR stands out as a leader in custom infrared solutions for manufacturing. The company offers a wide range of quartz infrared lamps and drying systems, tailored to unique production requirements. Their expertise ensures optimal heat delivery for every application.

Discover high-quality Quartz Infrared Lamps & Drying Systems made in the USA to enhance your industrial heating solutions today.

Heater Type | Characteristics and Industrial Applications |

|---|---|

Quartz Infrared | Rapid, intense heat; ideal for curing and heating plastics. |

Ceramic Infrared | Affordable; suitable for general industrial heating. |

Metal-Sheathed IR | Durable; used in robust industrial heating processes. |

General Use | Drying, curing, and heating plastics, paint, and organic materials with fast heat-up times. |

Custom infrared heating solutions transform manufacturing efficiency. These systems reduce downtime by allowing retrofits and upgrades that extend equipment life. Production speed and capacity increase as heating systems adapt to higher demands and new materials. High-spec infrared components and advanced controls lower operational costs by improving energy efficiency. Manufacturers achieve precise process control with closed-loop and multi-zone systems, optimizing heat application and preventing waste. Consistent, even heat throughout large factory spaces enhances worker comfort and productivity, which can boost employee focus and performance. YFR’s custom-engineered systems match facility size, ceiling height, and specific heat requirements, ensuring optimal performance and energy use.

In 2025, manufacturing trends highlight the growing adoption of smart, modular infrared heating systems. Companies seek solutions that integrate seamlessly with automation platforms, enabling remote monitoring and adjustment of heating parameters. Sustainability remains a top priority, with manufacturers choosing energy-efficient infrared heater bulbs to meet regulatory standards and reduce emissions. The demand for tailored heating solutions continues to rise, as businesses require systems that fit unique production lines and materials. YFR’s commitment to innovation and American manufacturing positions the company as a preferred partner for manufacturers aiming to stay competitive in a rapidly evolving market.

Automotive manufacturers rely on advanced heating technologies to achieve flawless paint finishes. Infrared heater bulbs play a crucial role in this process. Medium wavelength infrared energy is absorbed directly by automotive coatings, enabling uniform and efficient curing. This method allows the paint to dry from the inside out, which prevents common defects such as skin or bubble formation on the surface. High energy, short wavelength infrared is especially effective for complex vehicle shapes and areas that are difficult to reach, as it heats both the paint and the underlying substrate.

Manufacturers can optimize process flow and energy use by matching the infrared spectrum to the specific paint and substrate. Adjustable temperature ranges and working distances provide precise control, resulting in cleaner finishes and reduced curing times—often accelerated by 60% to 80%. The contactless nature of infrared curing also eliminates the risk of secondary pollution, supporting environmental protection initiatives. Safety features, such as automatic overload protection and focused heating, ensure that only the intended surfaces receive heat, further enhancing operational safety.

YFR supplies high-quality quartz infrared heater bulbs that deliver consistent, reliable performance in automotive spray booths and local paint drying stations. Their products help manufacturers achieve rapid, defect-free curing while maintaining energy efficiency.

Infrared heating technology has transformed automotive assembly lines. Manufacturers use infrared heater bulbs to automate quality testing and accelerate adhesive curing. For example, automotive window demisters undergo automated testing with infrared temperature monitoring, reducing manual inspection time from up to 15 minutes to just 30 seconds. This automation not only speeds up the assembly line but also frees employees to focus on other critical tasks.

Infrared systems provide real-time temperature measurements, quickly detecting defects in heating wires or adhesives. If temperature thresholds are not met, the system can trigger alarms or automated responses, ensuring consistent quality. Infrared heating also improves the adhesion of thermoplastic sealings to automotive glass and optimizes vacuum laminating processes for plastic parts like dashboards and door panels. Fast, precise heating of adhesives ensures secure bonding, as seen in advanced moon roof assemblies. These improvements lead to higher production speed, better fit, and enhanced durability of interior components.

Automotive manufacturers demand the highest standards for finish and durability. Infrared heater bulbs contribute to these goals by delivering uniform heat distribution and precise temperature control. This technology prevents surface defects, such as scorching or uneven curing, and ensures that coatings and adhesives perform as intended. The ability to cure hidden or hard-to-reach areas through conduction and convection further enhances product quality.

Durable construction and advanced safety features in modern infrared systems support stable operation and long service life. Regular maintenance of emitters and reflectors maintains curing consistency, while modular designs allow for easy upgrades as production needs evolve. YFR’s commitment to quality and innovation ensures that automotive clients receive reliable, high-performance heating solutions tailored to their specific requirements.

Automotive manufacturers continue to embrace infrared heater bulbs as a cornerstone of their production strategies in 2025. Several key trends define the landscape for this technology within the sector.

1. Smart Automation and Integration

Automotive plants now integrate infrared heating systems with advanced automation platforms. These systems connect directly to robotics and process control software. Operators monitor and adjust heating parameters in real time. This integration ensures precise temperature management for every vehicle component. Automated quality checks use infrared sensors to detect inconsistencies instantly. As a result, manufacturers achieve higher throughput and fewer defects.

2. Sustainability and Energy Efficiency

Environmental responsibility drives many decisions in the automotive industry. Companies seek to reduce their carbon footprint and comply with strict emissions standards. Infrared heater bulbs offer direct, targeted heating that minimizes energy waste. Plants report up to 30% reductions in energy consumption after switching to modern infrared systems. Many manufacturers now highlight these savings in their annual sustainability reports.

3. Customization for New Materials

Automotive design evolves rapidly. Manufacturers use new lightweight materials, advanced coatings, and composite structures. Infrared heater bulbs adapt easily to these changes. Engineers select specific wavelengths and power levels to match the unique properties of each material. This flexibility supports innovation in electric vehicles, autonomous platforms, and specialty vehicles.

4. Enhanced Safety and Workplace Comfort

Safety remains a top priority. Modern infrared heating systems include advanced safety features such as automatic shutoff, overload protection, and real-time diagnostics. These features protect both workers and equipment. Plants also use infrared heating to maintain comfortable working conditions, especially in large or open assembly areas.

5. Supply Chain Resilience and Domestic Sourcing

Recent global events have underscored the importance of reliable supply chains. Automotive companies now prioritize suppliers with domestic manufacturing capabilities. YFR, based in Michigan, delivers American-made quartz infrared lamps and systems. This local sourcing ensures consistent quality and timely delivery, reducing production delays.

Note: Industry analysts predict continued growth in the adoption of infrared heater bulbs across automotive manufacturing. Companies that invest in advanced heating solutions position themselves for greater efficiency, improved product quality, and long-term competitiveness.

Trend | Impact on Automotive Manufacturing |

|---|---|

Smart Automation | Higher throughput, fewer defects |

Sustainability | Lower energy use, reduced emissions |

Customization | Support for new materials and designs |

Enhanced Safety | Safer workplaces, equipment protection |

Supply Chain Resilience | Reliable sourcing, minimized disruptions |

Automotive leaders recognize that infrared heating technology will remain essential for meeting the demands of modern vehicle production. YFR’s commitment to innovation and quality positions the company as a trusted partner for the industry’s future.

Infrared heater bulbs have transformed baking operations in the food industry. Since the 1950s, bakeries have used infrared ovens to bake bread more efficiently. This technology delivers heat directly to the surface and penetrates 2–3 millimeters into the dough. As a result, baked goods reach optimal temperatures faster than in conventional ovens. The process shortens baking times, retains more moisture in the center, and extends shelf life. Bakeries benefit from precise temperature control, which ensures even browning and consistent texture. Infrared baking also reduces waiting time between batches, allowing for higher throughput and improved product quality.

Infrared baking heats food quickly and evenly.

Operators can control temperatures with precision, reducing the risk of overbaking.

The method preserves moisture, resulting in softer bread and pastries.

Food processors rely on infrared heater bulbs for effective sterilization. The bulbs emit direct radiation that kills bacteria and molds without the need for heat transfer mediums. This approach maintains hygiene standards and extends the shelf life of packaged foods. Infrared sterilization works on a wide range of products, including powders, nuts, grains, and blocks. For example, processors heat pumpkin seeds above 100°C for five minutes to reduce germs before packaging. Carbon infrared systems can also reduce mold on bread, extending shelf life by three to four days with only a few seconds of exposure.

Infrared sterilization operates as a non-contact, chemical-free process.

The method supports food safety by eliminating pathogens quickly.

Processors can apply infrared heat to various food types, enhancing versatility.

Consistency remains a top priority in food processing. Infrared heater bulbs deliver uniform heat, which ensures that every batch meets strict quality standards. The technology enhances product appearance, aroma, and texture. For example, infrared drying preserves the aroma of mushrooms and increases the crispiness of raspberries and Chinese yam. Operators observe better coloration and moisture control, which leads to higher consumer satisfaction.

Infrared heating systems also contribute to sustainability. They reduce energy consumption and drying times, making operations more efficient and environmentally friendly.

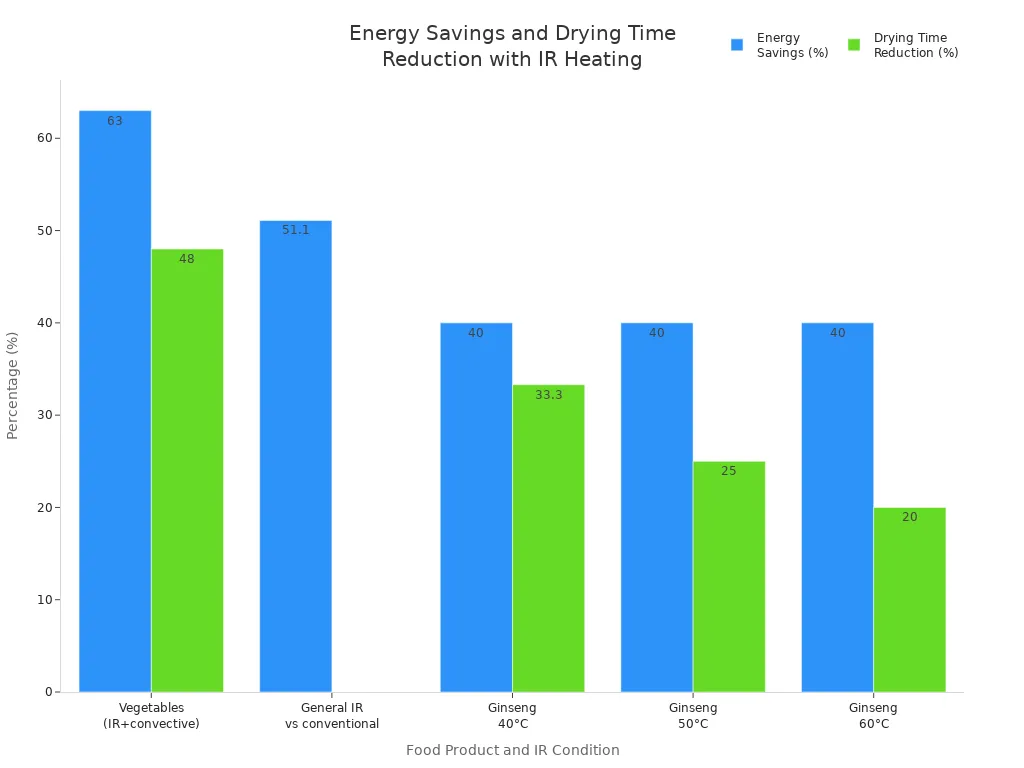

Food Product | IR Conditions / Parameters | Energy Savings / Drying Time Reduction / Quality Improvements |

|---|---|---|

Vegetables | IR + convective drying | 48% less drying time; 63% less energy use |

General IR drying | IR drying alone | Up to 51.1% less energy use |

Ginseng | FIR drying at 40–60°C | Drying time cut by up to 33.3%; energy use down by 40% |

Mushroom | IR intensity: 5.8 kW/m²; cold temp: −35 to −40°C | Faster drying; better aroma retention |

Raspberries | IR + microwave-vacuum drying | Drying time halved; crispiness doubled |

Chinese Yam | IR + heat pump drying | Higher crispiness, better color at 1000 W FIR |

Grated Carrot | Temp: 45–50°C; IR lamp: 2.5 µm | Improved energy efficiency; moisture content reduced significantly |

Food processors who adopt infrared heater bulbs achieve measurable improvements in efficiency, product quality, and sustainability. The technology supports rapid, uniform heating and helps companies meet modern food safety and environmental standards.

Sustainability has become a core value in the food processing industry. Companies now prioritize technologies that reduce environmental impact and support long-term resource management. Infrared heater bulbs play a significant role in helping food processors achieve these goals.

Infrared heating systems deliver energy directly to food products and surfaces. This targeted approach minimizes heat loss and reduces overall energy consumption. Many facilities report energy savings of up to 50% compared to traditional convection ovens or steam-based systems. Lower energy use translates to reduced greenhouse gas emissions, supporting corporate sustainability initiatives and compliance with environmental regulations.

Food processors also benefit from the rapid response time of infrared heater bulbs. These systems reach operating temperatures quickly, which shortens production cycles and decreases idle time. Shorter cycles mean less energy wasted during startup and shutdown phases. Facilities can process more batches per day without increasing their carbon footprint.

Water conservation represents another advantage. Traditional steam-based sterilization and cooking methods require large volumes of water. Infrared heating eliminates the need for water as a heat transfer medium. This shift helps companies reduce water usage and wastewater generation, which aligns with global efforts to preserve freshwater resources.

Many leading food brands now highlight their use of energy-efficient infrared heating in sustainability reports. These companies demonstrate a commitment to reducing their environmental impact while maintaining high product quality.

Sustainable food processing also involves waste reduction. Infrared heater bulbs provide precise temperature control, which reduces the risk of overcooking or burning. Consistent heating ensures that fewer products are discarded due to quality defects. Less waste means lower disposal costs and a smaller environmental footprint.

The table below summarizes the key sustainability benefits of infrared heater bulbs in food processing:

Sustainability Benefit | Impact on Food Processing |

|---|---|

Energy Efficiency | Up to 50% less energy use |

Reduced Emissions | Lower greenhouse gas output |

Water Conservation | Minimal water required for heating |

Waste Reduction | Fewer defective products, less food waste |

Compliance | Easier adherence to environmental regulations |

YFR supports the food industry’s sustainability journey by providing advanced quartz infrared lamps and custom heating systems. Their solutions help processors meet both operational and environmental goals. As sustainability standards continue to evolve, infrared heater bulbs will remain essential for food companies seeking efficient, eco-friendly production methods.

Infrared heater bulbs have become essential in medical equipment sterilization. Hospitals and laboratories rely on these devices to maintain sterile environments and prevent infection. Tungsten halogen lamps, a common type of infrared heater bulb, deliver rapid and intense heat. These bulbs reach temperatures between 900°C and 1300°C within seconds. This high heat destroys bacteria, viruses, and spores on medical instruments.

Infrared sterilizers operate without flammable gases or open flames, reducing fire risks.

The devices consume low energy and require no preheating, which saves time and resources.

Oxygen levels remain unchanged during operation, allowing use in anaerobic chambers.

Infrared sensor controls enable automatic start and shutdown after each sterilization cycle.

The sterilization area accommodates items up to 15 mm in diameter and 100 mm in length.

Hospitals, research labs, and clinics use these sterilizers for pipettes, needles, and small tools.

YFR provides advanced quartz infrared lamps designed for medical sterilization. Their products deliver reliable performance and help healthcare facilities meet strict hygiene standards.

Patient warming represents another critical application for infrared heating technology in healthcare. Medical teams use warming devices to maintain patient body temperature during surgery or recovery. Stable temperatures reduce the risk of hypothermia and improve patient outcomes. Infrared heater bulbs offer gentle, direct heat that does not disturb the surrounding air. This method supports patient comfort and safety in operating rooms, intensive care units, and recovery wards.

YFR’s commitment to quality ensures that their infrared heating solutions meet the unique needs of patient care. Their lamps provide consistent warmth, rapid response times, and easy integration with existing medical equipment. Healthcare providers trust YFR’s products to deliver safe and effective warming for patients of all ages.

Safety remains a top priority in medical environments. Infrared heater bulbs used in healthcare must comply with rigorous standards and certifications. These requirements ensure that devices operate safely and do not pose risks to patients or staff.

Standard / Certification | Description | Relevance to Medical Infrared Heater Bulbs |

|---|---|---|

IEC 60601-1 & 60601-1-11 | General safety for medical electrical devices, including home use | Mandatory for devices in hospitals and home care |

IEC 60601-1-2 | Electromagnetic compatibility (EMC) | Ensures safe operation near other medical electronics |

IEC 60601-2-57 & IEC 60601-2-83 | Specific safety for light therapy equipment | Directly applies to infrared heater bulbs in medical light therapy |

IEC 62471 | Photobiological safety for lamps and lamp systems | Protects users from potential photobiological hazards |

Third-Party Safety Verification | Independent testing (e.g., Intertek ETL mark) | Confirms compliance and builds trust with healthcare providers |

YFR designs and manufactures infrared heater bulbs that meet or exceed these safety standards. Their products undergo rigorous testing and third-party verification. Healthcare organizations can rely on YFR’s expertise and dedication to safety when selecting infrared heating solutions for medical applications.

The medical industry continues to evolve rapidly in 2025. Infrared heater bulbs play a central role in this transformation. Hospitals and clinics seek advanced heating solutions that improve patient outcomes, increase operational efficiency, and meet strict safety standards. Several key trends define the direction of medical infrared heating technology.

1. Smart Integration and Automation

Healthcare facilities now integrate infrared heater bulbs with smart monitoring systems. These systems allow staff to control temperature and sterilization cycles remotely. Automated alerts notify teams when equipment requires maintenance or calibration. This integration reduces human error and ensures consistent sterilization and patient warming.

2. Focus on Infection Control

Infection prevention remains a top priority. Medical teams use infrared heater bulbs for rapid, contactless sterilization of instruments and surfaces. The technology supports compliance with evolving hygiene protocols. Hospitals report fewer hospital-acquired infections after adopting advanced infrared sterilization systems.

3. Energy Efficiency and Sustainability

Healthcare organizations face increasing pressure to reduce energy consumption. Infrared heater bulbs offer direct, targeted heating that minimizes waste. Facilities report up to 40% lower energy use compared to traditional heating methods. Many hospitals now include energy-efficient infrared systems in their sustainability initiatives.

4. Customization for Specialized Care

Medical environments require tailored solutions. Manufacturers design infrared heater bulbs in various shapes, wattages, and wavelengths to meet specific needs. For example, neonatal units use gentle, low-intensity bulbs for infant warming. Surgical suites rely on high-intensity bulbs for rapid instrument sterilization. Customization ensures optimal performance in every department.

5. Regulatory Compliance and Safety

Regulatory agencies continue to update safety standards for medical devices. Infrared heater bulbs must meet rigorous certifications, including IEC and FDA requirements. Manufacturers like YFR invest in third-party testing and documentation. This commitment builds trust with healthcare providers and ensures patient safety.

6. Remote and Home Healthcare Expansion

The rise of telemedicine and home healthcare creates new opportunities for infrared heating technology. Portable infrared devices support patient care outside traditional hospital settings. These devices provide safe, effective warming and sterilization for home-based treatments.

Note: YFR leads the industry by developing innovative, American-made infrared heater bulbs that address these trends. Their products combine advanced safety features, energy efficiency, and smart integration. Healthcare providers trust YFR to deliver reliable solutions for modern medical environments.

Trend | Impact on Healthcare Facilities |

|---|---|

Smart Integration | Improved workflow, reduced errors |

Infection Control | Enhanced hygiene, fewer infections |

Energy Efficiency | Lower costs, greener operations |

Customization | Better patient outcomes, specialized care |

Regulatory Compliance | Safer devices, increased trust |

Home Healthcare Expansion | Greater access, flexible treatment options |

Medical professionals recognize the value of infrared heater bulbs in delivering safe, efficient, and patient-centered care. As technology advances, these trends will shape the future of medical heating solutions.

Electronics manufacturing demands precision and reliability, especially during soldering processes. Infrared heater bulbs have become essential tools for achieving high-quality solder joints on printed circuit boards (PCBs). Quartz infrared heating lamps deliver rapid and even heat, allowing manufacturers to reach optimal soldering temperatures quickly. This precise temperature control ensures that solder flows smoothly and bonds securely to electronic components. Uniform heating reduces the risk of cold solder joints and minimizes the chance of damaging sensitive parts.

Infrared heater bulbs also play a critical role in wave soldering. In this process, the lamps preheat PCBs before immersion in molten solder. Preheating helps prevent thermal shock and improves solder flow, resulting in fewer defects and less rework. Manufacturers benefit from faster cycle times and improved product consistency. YFR provides advanced quartz infrared lamps designed for these demanding applications, supporting efficient and reliable electronics assembly.

Printed circuit boards require thorough drying after cleaning, coating, or soldering. Infrared heater bulbs offer a superior solution for this stage. These lamps emit targeted infrared energy that penetrates moisture on and within the PCB layers. The result is rapid and uniform moisture removal, which helps maintain the integrity of delicate circuits and components.

Electronics manufacturers value the efficiency of infrared drying systems. The technology reduces drying times and increases production throughput. Uniform heat distribution prevents warping or uneven drying, which can compromise board quality. Infrared LED heat lamp PCBs, equipped with thermal management features like heat sinks and thermal pads, further enhance performance and longevity. YFR’s custom infrared solutions ensure that each drying process matches the specific needs of the production line, delivering consistent results every time.

Key benefits of infrared PCB drying:

Fast and uniform moisture removal

Protection of sensitive electronic components

Enhanced production speed and quality

Thermal stress poses a significant challenge in electronics manufacturing. Sudden or uneven temperature changes can damage components, cause solder cracks, or lead to board warping. Infrared heater bulbs address this issue by providing controlled, gradual heating and cooling cycles. This approach minimizes thermal gradients across the PCB, reducing the risk of stress-related failures.

Manufacturers use infrared heat during inspection and testing phases as well. By applying controlled infrared energy, they can detect soldering defects non-invasively, ensuring product reliability before final assembly. The precise temperature control offered by quartz and LED infrared lamps supports both process stability and product longevity.

YFR’s infrared heating solutions help electronics manufacturers achieve high yields, reduce waste, and maintain the highest standards of quality. Their expertise in custom lamp design and integration ensures optimal performance for every application.

Electronics manufacturing in 2025 continues to evolve at a rapid pace. Infrared heater bulbs play a central role in this transformation. Several trends define the direction of the industry and shape how manufacturers approach heating processes.

1. Smart Automation and Precision Control

Manufacturers now integrate infrared heating systems with advanced automation platforms. These systems connect to sensors and software that monitor temperature in real time. Operators can adjust heating profiles for each production batch. This level of control ensures consistent soldering and drying results. Automated systems also reduce human error and improve overall product quality.

2. Miniaturization and High-Density Assemblies

Electronic devices become smaller and more complex each year. Manufacturers must solder and dry components on densely packed circuit boards. Infrared heater bulbs deliver targeted heat without damaging sensitive parts. The technology supports the production of smartphones, wearables, and medical devices that require precise thermal management.

3. Sustainability and Energy Efficiency

Energy consumption remains a top concern for electronics manufacturers. Infrared heating systems offer direct, focused energy transfer. Facilities report up to 40% reductions in energy use compared to traditional convection ovens. Lower energy consumption leads to reduced operating costs and supports environmental goals. Many companies now highlight their use of energy-efficient infrared systems in sustainability reports.

4. Customization and Flexible Manufacturing

Production lines must adapt quickly to new products and changing customer demands. Manufacturers choose modular infrared heating systems that allow for easy upgrades and reconfiguration. Custom-shaped infrared heater bulbs fit unique equipment layouts. YFR provides a wide range of lamp sizes, wattages, and voltages to meet these needs.

5. Supply Chain Resilience and Domestic Sourcing

Recent disruptions have shown the importance of reliable supply chains. Electronics companies now prefer suppliers with domestic manufacturing capabilities. YFR, based in Michigan, delivers American-made quartz infrared lamps and systems. This local sourcing ensures fast delivery and consistent quality.

Note: Industry experts predict continued growth in the adoption of infrared heater bulbs for electronics manufacturing. Companies that invest in advanced heating solutions position themselves for greater efficiency, higher product quality, and long-term competitiveness.

Trend | Impact on Electronics Manufacturing |

|---|---|

Smart Automation | Consistent results, fewer errors |

Miniaturization | Supports complex, high-density assemblies |

Sustainability | Lower energy use, greener operations |

Customization | Flexible production, rapid adaptation |

Supply Chain Resilience | Reliable sourcing, minimized disruptions |

YFR stands at the forefront of these trends. The company’s expertise in custom infrared solutions helps electronics manufacturers meet the demands of a fast-changing industry. Their commitment to innovation and quality ensures that clients receive reliable, efficient heating systems for every application.

Plastics manufacturing relies on precise temperature control during molding processes. Infrared heater bulbs deliver rapid, contact-free heating that adapts to the shape and requirements of each product. Manufacturers use these bulbs to heat molds quickly and evenly, which is essential for complex parts and high-volume production. Infrared emitters can be shaped to match product contours, automating tasks like welding, deburring, and adhesive activation. This flexibility supports a wide range of applications, including the welding of polypropylene containers, laminating automotive components, embossing floor coverings, and shaping dashboards.

Infrared heating systems integrated into molds enable rapid surface heating. This approach reduces cycle times and enhances product quality by ensuring uniform temperature distribution across the mold surface. Optimized reflector geometry concentrates infrared energy where it is needed most, supporting faster and more efficient molding cycles.

Efficient heating and cooling cycles are critical for productivity in plastics manufacturing. Infrared heater bulbs switch on and off within seconds, allowing for precise control over each stage of the process. This rapid response minimizes energy waste and supports automation of complex shaping and joining tasks. Compared to traditional methods like hot air or heating baths, infrared emitters heat plastic foils and parts much faster, reducing overall cycle times and energy consumption.

Infrared heating improves temperature uniformity, which is vital for consistent results.

Systems can dry coatings and adhesives efficiently without damaging sensitive plastics.

Manufacturers can automate processes such as bending and shaping plastic pipes, increasing throughput and reducing manual labor.

Numerical modeling and real-world experiments show that rapid heat cycle molding (RHCM) with infrared heating significantly improves both heating and cooling efficiency. Optimized mold designs and targeted heating methods can reduce cycle times to about 72 seconds, boosting productivity and supporting higher output.

Product quality remains a top priority for plastics manufacturers. Infrared heater bulbs deliver precise, controllable heat directly to plastic surfaces, ensuring uniform temperature distribution. This uniformity prevents local overheating and sticking of plastic particles, which can lead to defects. Carbon fiber infrared heater elements, for example, improve drying efficiency and temperature control during dehydration and thermoforming. Manufacturers report energy savings of up to 50% and efficiency gains of 20% to 30% after adopting infrared heating.

Improved efficiency through decreased energy usage and increased production

Reduced scrap and downtime

Elimination of hot spots and uneven heating

Better resultant product quality

More complex parts possible

Improved setup and faster tool change times

Heating controls matched to polymers processed

Reduced cooling requirements

Enhanced operator environment

Infrared heating also supports better thermoforming by heating plastic sheets evenly, prevents material degradation during welding, and ensures consistent curing of composites. These advantages contribute to enhanced surface quality, reduced defects, and greater operational effectiveness. YFR offers custom infrared heater bulb options tailored to the specific needs of plastics manufacturers, helping them achieve superior results in molding, forming, and rapid heating or cooling applications.

The plastics industry continues to evolve rapidly in 2025. Infrared heater bulbs play a central role in this transformation. Several key trends define how manufacturers approach molding, forming, and rapid heating or cooling.

1. Smart Manufacturing Integration

Manufacturers now integrate infrared heating systems with smart factory platforms. These systems connect to sensors and automation software. Operators monitor and adjust heating parameters in real time. This integration leads to precise temperature control and consistent product quality. Facilities report fewer defects and higher throughput.

2. Customization and Modular Design

Demand for custom plastic parts rises across automotive, medical, and consumer goods sectors. Manufacturers require heating solutions tailored to unique shapes and production lines. YFR responds by offering custom infrared heater bulbs in a wide range of sizes, wattages, and voltages. Modular heating systems allow for quick upgrades and easy maintenance. This flexibility supports rapid product development and shorter lead times.

3. Energy Efficiency and Sustainability

Energy costs remain a top concern for plastics processors. Infrared heater bulbs deliver direct, targeted heat, reducing energy waste. Facilities report up to 50% lower energy consumption compared to traditional methods. Many companies now highlight their use of energy-efficient infrared systems in sustainability reports. Reduced emissions and lower operating costs support both environmental goals and profitability.

4. Advanced Materials and Composite Processing

The rise of advanced polymers and composites creates new challenges for heating technology. Infrared heater bulbs adapt to these materials by providing precise wavelength and intensity control. Manufacturers achieve better surface finishes and improved mechanical properties. This capability supports innovation in lightweight automotive parts, medical devices, and high-performance packaging.

5. Automation and Quality Assurance

Automation continues to shape plastics manufacturing. Infrared heating systems now feature integrated quality monitoring. Sensors detect temperature variations and trigger adjustments automatically. This approach ensures uniform heating and reduces scrap rates. Operators spend less time on manual inspections and more time on value-added tasks.

YFR leads the industry by delivering American-made, custom infrared heating solutions that address these trends. Their expertise helps plastics manufacturers stay competitive in a fast-changing market.

Trend | Impact on Plastics Manufacturing |

|---|---|

Smart Integration | Real-time control, fewer defects |

Customization | Flexible production, faster development |

Energy Efficiency | Lower costs, greener operations |

Advanced Materials | Better quality, supports innovation |

Automation | Higher yields, reduced manual labor |

Plastics manufacturers recognize that infrared heater bulbs will remain essential for efficient, high-quality production. YFR’s commitment to innovation and customer service positions them as a trusted partner for the future of plastics processing.

Aerospace manufacturers rely on advanced materials to build lighter, stronger, and more fuel-efficient aircraft. Composite materials, such as carbon fiber reinforced polymers, require precise curing processes to achieve optimal strength and durability. Quartz infrared heater bulbs play a vital role in this stage. These bulbs emit high-intensity short-wave or medium-wave infrared radiation, delivering heat directly to composite surfaces. This targeted approach ensures uniform temperature distribution across large and complex parts.

Infrared heating allows engineers to control the curing process with exceptional accuracy. The technology enables composite materials to reach and maintain specific temperatures, which enhances mechanical properties and structural stability. Aircraft manufacturers report that infrared curing reduces cycle times and increases throughput. In painted aircraft assemblies, infrared heating technology has demonstrated the ability to cut curing times by over 75%. This improvement accelerates production schedules and helps companies meet tight delivery deadlines.

YFR’s advanced quartz infrared lamps provide the uniform and controllable heat source required for aerospace composite curing. Their custom solutions support both small component fabrication and large fuselage assembly lines.

Surface treatment processes in aerospace manufacturing demand both speed and precision. Infrared heater bulbs deliver rapid and even heat, making them ideal for applications such as metal welding, annealing, and paint drying. The direct heating capability of quartz infrared lamps minimizes energy loss and ensures that only the intended surfaces receive heat.

Infrared heating improves weld quality by reducing the risk of material stress or cracks.

Annealing with infrared lamps enhances the ductility and toughness of metal components.

Paint drying benefits from uniform heat, resulting in smoother finishes and fewer defects.

Technicians value the ability to adjust heat intensity and wavelength to match different materials and coatings. This flexibility supports a wide range of surface treatments, from delicate aluminum alloys to robust titanium structures. Infrared systems also integrate easily with automated production lines, supporting consistent results and high-quality standards.

Reliability stands as a cornerstone in aerospace operations. Every component must perform flawlessly under extreme conditions. Infrared heater bulbs contribute to this reliability by providing consistent, repeatable heating processes. Uniform heat application reduces the risk of warping, incomplete curing, or surface imperfections.

Aerospace engineers trust infrared heating for its rapid response and precise control. The technology supports strict quality assurance protocols, ensuring that each part meets rigorous industry standards. YFR’s quartz infrared lamps undergo thorough testing and quality checks before deployment. Their robust construction and long service life make them a dependable choice for aerospace manufacturers worldwide.

Aerospace companies that adopt advanced infrared heating solutions gain a competitive edge through faster production, improved material performance, and enhanced operational reliability.

The aerospace industry continues to evolve rapidly in 2025. Infrared heater bulbs play a pivotal role in this transformation. Several trends shape how manufacturers and maintenance teams use this technology to improve efficiency, safety, and sustainability.

1. Smart Manufacturing and Automation

Aerospace companies now integrate infrared heating systems with advanced automation platforms. These systems connect to sensors and control software. Operators monitor and adjust heating parameters in real time. This integration ensures precise temperature control during composite curing and surface treatments. Automated systems reduce human error and increase production speed.

2. Advanced Composite Materials

Aircraft manufacturers increasingly use advanced composites for lighter and stronger structures. Infrared heater bulbs provide the precise, uniform heat required for curing these materials. Engineers select specific wavelengths to match the thermal properties of each composite. This approach improves material performance and reduces cycle times.

3. De-Icing and On-Site Maintenance

Infrared heating technology supports rapid de-icing of aircraft surfaces. Maintenance teams use portable infrared systems to remove ice and snow efficiently. This method reduces turnaround times and enhances safety during winter operations. Infrared bulbs also assist in on-site repairs by delivering targeted heat for bonding and curing.

4. Sustainability and Energy Efficiency

Environmental concerns drive the adoption of energy-efficient technologies. Infrared heater bulbs deliver direct, focused heat, minimizing energy waste. Aerospace facilities report significant reductions in energy consumption and emissions. Many companies now include infrared heating in their sustainability initiatives.

5. Customization and Modular Solutions

Aerospace projects often require tailored heating solutions. Manufacturers demand infrared heater bulbs in custom shapes, wattages, and voltages. Modular systems allow for quick upgrades and easy maintenance. This flexibility supports rapid adaptation to new aircraft designs and production requirements.

6. Supply Chain Resilience and Domestic Sourcing

Recent global events highlight the need for reliable supply chains. Aerospace companies prefer suppliers with domestic manufacturing capabilities. YFR, based in Michigan, delivers American-made quartz infrared lamps and systems. This local sourcing ensures consistent quality and timely delivery.

YFR leads the industry by offering advanced, customizable infrared heating solutions for aerospace applications. Their expertise supports composite curing, de-icing, and surface treatment processes. Aerospace manufacturers trust YFR for reliable performance and innovative technology.

Trend | Impact on Aerospace Industry |

|---|---|

Smart Automation | Higher precision, faster production |

Advanced Composites | Improved material performance |

De-Icing & Maintenance | Reduced downtime, enhanced safety |

Sustainability | Lower energy use, greener operations |

Customization | Flexible solutions for unique needs |

Supply Chain Resilience | Reliable sourcing, minimized disruptions |

Aerospace leaders recognize that infrared heater bulbs will remain essential for meeting the demands of modern aircraft production and maintenance. YFR’s commitment to innovation and quality positions them as a trusted partner for the future of aerospace technology.

Chemical processing industries require precise temperature management to ensure product quality and process safety. Infrared heater bulbs deliver targeted, controllable heat, making them ideal for these demanding environments. Quartz infrared heaters stand out for their rapid heating capabilities and durability. Ceramic heaters, which emit medium to long-wave infrared radiation, are also widely used in chemical processing for their ability to provide steady, direct heat.

Quartz and ceramic infrared heaters offer rapid response times, supporting fast process adjustments.

These heaters emit radiant energy that warms only the intended objects or surfaces, preventing unnecessary heating of the surrounding air.

Reflective surfaces paired with heating elements direct energy efficiently, while protective enclosures enhance safety and equipment longevity.

Integrated temperature controllers and sensors allow operators to maintain strict temperature tolerances, which is critical for sensitive chemical reactions.

The use of electromagnetic waves enables these heaters to function effectively in various chemical environments, supporting both batch and continuous processes.

YFR’s infrared heating solutions incorporate advanced control technologies, ensuring that chemical manufacturers achieve consistent results and operational reliability.

Safety remains a top priority in chemical processing facilities. Infrared heater bulbs contribute to safer operations by minimizing direct contact with hot surfaces and reducing the risk of accidental burns. Electric infrared heaters do not produce open flames, gaseous pollutants, or toxic fumes, which helps maintain a cleaner and safer workplace.

Infrared heaters do not disturb dust or allergens, improving air quality and reducing respiratory risks for workers.

Engineering controls, such as protective shields and enclosures, further mitigate potential hazards like burns or eye exposure to intense radiation.

The absence of combustion in electric infrared systems eliminates the risk of fire and lowers the potential for hazardous emissions.

YFR designs its infrared heating products to comply with rigorous industry safety standards, providing chemical plants with peace of mind and dependable performance.

By integrating these safety features, chemical facilities can focus on process efficiency without compromising worker well-being.

Environmental stewardship is increasingly important in the chemical industry. Infrared heater bulbs support sustainability goals by delivering energy directly to process materials, which reduces overall energy consumption and associated emissions.

Infrared heaters operate with high efficiency, lowering greenhouse gas output compared to traditional heating methods.

Electric infrared systems do not emit nitrogen oxides (NOx), carbon monoxide (CO), or particulates, contributing to a cleaner production environment.

The technology’s ability to provide rapid, uniform heating can shorten production cycles, further decreasing energy use and environmental impact.

Infrared heating does not disturb dust or release allergens, supporting healthier workplace conditions.

YFR’s commitment to environmentally responsible manufacturing ensures that its infrared heating solutions help chemical processors meet both regulatory requirements and corporate sustainability targets. As the industry continues to prioritize green practices, infrared heater bulbs will remain a key technology for safe, efficient, and eco-friendly chemical processing.

The chemical industry continues to evolve as new technologies and regulations shape its future. Infrared heater bulbs have become a cornerstone for safe, efficient, and sustainable heating in chemical processing. Several key trends define how chemical plants and laboratories use this technology in 2025.

1. Digital Integration and Smart Controls

Chemical facilities now integrate infrared heating systems with digital monitoring platforms. Operators use real-time data to adjust temperatures and optimize energy use. Smart sensors track performance and alert staff to maintenance needs. This approach reduces downtime and improves process reliability.

2. Focus on Sustainability

Environmental responsibility drives many decisions in the chemical sector. Companies adopt infrared heater bulbs to lower energy consumption and reduce emissions. Plants report measurable drops in greenhouse gas output after switching to electric infrared systems. Many organizations now include these improvements in their annual sustainability reports.

3. Customization for Specialized Processes

Chemical manufacturers require heating solutions tailored to unique reactions and materials. Infrared heater bulbs come in various shapes, wattages, and wavelengths. Engineers select the best configuration for each process. Custom fixtures and controls from YFR help companies achieve precise results and maintain product quality.

4. Enhanced Safety Standards

Safety remains a top priority. Infrared heating eliminates open flames and reduces the risk of fire or hazardous emissions. Facilities invest in systems that comply with strict industry standards, such as UL and IEC certifications. YFR’s products undergo rigorous testing to ensure safe operation in demanding environments.

5. Modular and Scalable Solutions

Chemical plants need flexibility as production demands change. Modular infrared heating systems allow for easy expansion or reconfiguration. Companies can add or remove heating zones without major disruptions. This scalability supports both pilot projects and large-scale operations.

6. Supply Chain Resilience and Domestic Sourcing

Recent global events highlight the importance of reliable suppliers. Chemical companies prefer American-made infrared heater bulbs for consistent quality and timely delivery. YFR’s Michigan-based manufacturing facility ensures secure shipping and dependable service.

Note: Industry experts predict continued growth in the adoption of infrared heating technology across the chemical sector. Companies that invest in advanced, compliant solutions position themselves for greater efficiency, safety, and environmental stewardship.

Trend | Impact on Chemical Industry |

|---|---|

Digital Integration | Improved control, reduced downtime |

Sustainability | Lower emissions, energy savings |

Customization | Process optimization, higher quality |

Enhanced Safety | Fewer incidents, regulatory compliance |

Modular Solutions | Flexible, scalable operations |

Supply Chain Resilience | Reliable sourcing, minimized disruptions |

YFR’s commitment to innovation and compliance positions the company as a trusted partner for chemical manufacturers. Their advanced infrared heating solutions help clients meet the challenges of a rapidly changing industry.

Mining operations demand reliable equipment performance in some of the world’s harshest environments. Maintenance depots in mining facilities use infrared heater bulbs to create controlled temperature zones. These zones allow technicians to service and repair machinery without delays caused by cold or damp conditions. Equipment enclosures, such as those housing grease pumping systems, benefit from targeted infrared heating. This approach prevents grease from thickening or freezing, which can lead to costly breakdowns.

Valves and moving parts in mining equipment often face the risk of clogging or seizing due to low temperatures. Spot heating with infrared bulbs keeps these components at optimal operating temperatures. This method ensures that critical systems remain functional, even during extreme weather. Maintenance teams also rely on the instant heat delivery of quartz infrared lamps. These lamps reach full power within one second, allowing for rapid response during urgent repairs

.

Use Case / Feature | Description |

|---|---|

Maintenance Depots | Provide controlled temperature environments for maintenance and repair of tools and machinery. |

Equipment Enclosures | Maintain temperature inside rooms or containers housing grease pumping equipment to prevent issues. |

Valves | Spot heating to prevent valve clogging or seizure, critical for equipment reliability. |

Instant Heat Delivery | Heaters reach full power within one second, ideal for dynamic mining operation needs. |

YFR’s robust quartz infrared heater bulbs deliver consistent performance in these demanding settings. Their products help mining companies reduce downtime, extend equipment life, and maintain productivity.

Mining sites often operate in remote, exposed locations where temperatures can drop rapidly. Workers require reliable heating solutions to stay safe and productive. Infrared heater bulbs provide spot heating in outdoor work areas, ensuring that personnel remain warm during shifts. Mining camps and living quarters also benefit from these systems. Consistent heating creates comfortable environments for workers, supporting morale and reducing the risk of cold-related illnesses.

Workstations scattered throughout a mine site use infrared heating to maintain optimal temperatures. This approach prevents disruptions caused by cold weather and helps teams focus on their tasks. Short-wave infrared technology concentrates heat exactly where it is needed, minimizing energy waste and heat loss. These systems operate efficiently, even in open or partially sheltered spaces.

YFR designs infrared heater bulbs with high ingress protection (IP) ratings. Their products withstand dust, moisture, and vibration, making them suitable for hazardous zones. Many models carry ATEX certification, ensuring safe operation in explosive atmospheres common in mining environments.

Durability stands as a key requirement for any heating solution used in mining. Quartz halogen infrared lamps from YFR offer long lamp life, often reaching up to 7,000 hours of continuous operation. This longevity reduces maintenance costs and limits the need for frequent replacements. The rugged construction of these bulbs ensures reliable performance despite constant exposure to dust, vibration, and temperature fluctuations.

Mining companies value the robust design and energy efficiency of YFR’s infrared heater bulbs. The lamps deliver consistent heat output over extended periods, supporting both equipment maintenance and on-site comfort. Their ability to function in hazardous and high-demand environments makes them a preferred choice for mining operations seeking dependable, long-term heating solutions.

Mining operations that invest in advanced infrared heating technology experience fewer equipment failures, improved worker safety, and lower operational costs. YFR’s commitment to quality and innovation positions them as a trusted partner for the mining industry’s toughest challenges.

The mining industry continues to evolve rapidly in 2025. Companies face new challenges and opportunities as technology advances and regulations tighten. Infrared heater bulbs play a central role in this transformation. Several trends define how mining operations use this technology to improve efficiency, safety, and sustainability.

1. Automation and Smart Monitoring

Mining companies invest in automated systems that monitor and control heating equipment. Sensors track temperature and performance in real time. Operators receive instant alerts if a heater malfunctions or if temperatures fall outside safe ranges. This approach reduces downtime and prevents costly equipment failures. Automated controls also help companies optimize energy use across large sites.

2. Enhanced Worker Safety

Safety remains a top priority in mining. Infrared heater bulbs provide targeted heat without open flames or exposed elements. This design reduces fire risks and protects workers from burns. Many mines now use infrared heating in hazardous zones where traditional heaters would pose safety concerns. YFR’s products meet strict safety standards, supporting safe operations in challenging environments.

3. Sustainability and Energy Efficiency

Mining companies seek to reduce their environmental impact. Infrared heater bulbs deliver direct, efficient heat, which lowers energy consumption. Facilities report significant reductions in fuel use and greenhouse gas emissions after switching to electric infrared systems. Many mines now include these improvements in their annual sustainability reports.

4. Customization for Harsh Environments

Every mine site presents unique challenges. Operators require heating solutions that withstand dust, moisture, and vibration. YFR offers custom quartz infrared heater bulbs with high ingress protection (IP) ratings. These products perform reliably in extreme temperatures and hazardous locations. Custom fixtures and controls ensure that each system matches the specific needs of the site.

5. Supply Chain Resilience and Domestic Sourcing

Recent global events highlight the importance of reliable suppliers. Mining companies prefer American-made infrared heater bulbs for consistent quality and timely delivery. YFR’s Michigan-based facility ensures secure shipping and dependable service, even to remote locations.

Note: Industry experts predict continued growth in the adoption of infrared heating technology across the mining sector. Companies that invest in advanced, robust solutions position themselves for greater efficiency, improved safety, and long-term sustainability.

Trend | Impact on Mining Operations |

|---|---|

Automation | Reduced downtime, optimized energy use |

Enhanced Safety | Fewer incidents, safer work environments |

Sustainability | Lower emissions, reduced energy costs |

Customization | Reliable performance in harsh conditions |

Supply Chain Resilience | Consistent quality, timely delivery |

Mining leaders recognize that infrared heater bulbs will remain essential for efficient, safe, and sustainable operations. YFR’s commitment to innovation and durability positions them as a trusted partner for the future of mining technology.

Infrared heater bulbs have revolutionized ink drying in the printing industry. These bulbs emit infrared radiation that inks and coatings absorb directly. The energy converts to heat, which rapidly dries or cures the ink. This process reduces drying times from minutes to seconds. Printers benefit from less smudging, offsetting, and ink bleeding. The technology supports a wide range of ink types, including water-based, solvent-based, UV-curable, and latex inks.

A high-speed printing machine in the UK used a Noblelight carbon infrared system to dry high-quality tickets more cost-efficiently.

Hybrid carbon infrared emitters dry water-soluble ink on multi-layer absorbent napkins.

Corrugator capacity improved for coated board production at a packaging factory using infrared drying systems.

Food packaging board coating operations saw significant energy cost reductions with carbon infrared emitters.

A printing group achieved the necessary drying speed for high-speed printing heads with infrared emitters.

Selecting the right infrared wavelength and power ensures optimal drying and curing for each ink type and printing speed. Compact integration into printing machines allows for efficient use of space and energy.

Speed remains a critical factor in modern printing operations. Infrared heater bulbs deliver targeted heating, which accelerates production lines. The direct application of heat to the ink layer means printers can move substrates through machines at higher speeds without sacrificing quality. This efficiency supports high-volume jobs and tight deadlines.

Infrared drying systems enable printers to meet demanding schedules while maintaining consistent results. The technology reduces operational costs by minimizing energy consumption and heat loss compared to conventional drying methods.

Combined infrared and hot air drying modules, now common in 2025, further enhance speed. These modules use hot air to remove moisture and cool the infrared lamp, extending lamp lifespan and supporting continuous operation. Cassette technology allows for quick lamp replacement, minimizing downtime.

Print quality defines a printer’s reputation. Infrared heater bulbs help achieve vibrant, defect-free prints. The rapid, uniform drying process ensures consistent color vibrancy and prevents defects such as mottling or uneven gloss. Targeted heating avoids overheating substrates, preserving material integrity.

Infrared emitters provide the necessary drying speed for high-speed printing heads, ensuring sharp, clear images.

Hybrid carbon infrared systems dry water-soluble inks on absorbent materials, maintaining print clarity and preventing ink migration.

Corrugated board and packaging benefit from improved surface finish and adhesion.

Specialized lamp technologies, including UV curing and hybrid infrared systems, offer additional benefits. UV curing lamps provide quick, effective ink curing for digital screen printing, resulting in glossy finishes and improved adhesion. The availability of diverse lamp types—shortwave, mediumwave, and longwave infrared—allows printing businesses to select solutions tailored to their specific needs.

Segment Category | Details |

|---|---|

Power Output | Low (up to 500W), Medium (500W-1500W), High (above 1500W) |

Technology Type | Conventional Infrared, LED Infrared, Hybrid Infrared |

Lamp Type | Shortwave, Mediumwave, Longwave Infrared |

Application | Industrial Curing, Commercial Printing, Packaging, Textile |

YFR’s specialized quartz infrared lamps support these advancements. Their products deliver reliable, efficient heat for ink drying and print quality improvements, helping printing businesses stay competitive in a fast-paced market.

The printing industry continues to evolve rapidly in 2025. Infrared heater bulbs drive many of these changes. Printers seek faster, more reliable, and energy-efficient solutions. Infrared technology meets these demands and shapes new industry standards.

Key trends in printing with infrared heater bulbs include:

Smart Integration and Automation

Printing businesses now integrate infrared drying systems with digital controls. Operators monitor and adjust lamp output in real time. Automated sensors detect substrate type and ink thickness. These systems optimize drying speed and energy use for each print job.

Sustainability and Energy Efficiency

Companies focus on reducing their environmental impact. Infrared heater bulbs use less energy than traditional drying methods. Printers report lower electricity bills and smaller carbon footprints. Many businesses highlight these savings in sustainability reports.

Customization and Modularity

Printers demand flexible solutions. Manufacturers offer modular infrared lamp systems. Operators can swap out lamps or adjust configurations for different print runs. Custom lamp shapes and wattages fit unique presses and specialty applications.

Advanced Materials and Inks

The rise of new substrates and specialty inks creates new challenges. Infrared heater bulbs adapt to these materials. Printers achieve consistent drying on plastics, textiles, and recycled papers. Infrared systems handle water-based, UV-curable, and solvent inks with equal efficiency.

Quality Assurance and Consistency

Print quality remains a top priority. Infrared drying delivers uniform results across large print runs. Sensors and feedback loops ensure every sheet receives the right amount of heat. This approach reduces defects and rework.

Supply Chain Resilience and Domestic Sourcing

Printers value reliable suppliers. Many now choose American-made infrared heater bulbs for consistent quality and fast delivery. YFR’s Michigan facility supports printing businesses across the country and worldwide.

Note: Industry experts predict continued growth in infrared drying technology. Printers who invest in advanced systems gain a competitive edge through faster turnaround, lower costs, and higher print quality.

Trend | Impact on Printing Businesses |

|---|---|

Smart Integration | Real-time control, optimized performance |

Sustainability | Lower energy use, greener operations |

Customization | Flexible setups, supports innovation |

Advanced Materials | Consistent results on new substrates |

Quality Assurance | Fewer defects, higher customer satisfaction |

Supply Chain Resilience | Reliable sourcing, timely delivery |

YFR leads the way with specialized quartz infrared lamps for printing. Their products help businesses meet modern demands and prepare for future challenges.

Homeowners increasingly choose infrared heater bulbs for efficient and reliable comfort heating. These systems deliver warmth directly to people and objects, rather than heating the air. This approach reduces energy waste and creates a cozy environment even in drafty spaces. Residents install infrared heaters in garages, workshops, basements, and patios to extend the usability of these areas throughout the year. The technology provides consistent, even heat that eliminates cold spots and supports zoned heating. Homeowners appreciate the low maintenance requirements and long service life, with many bulbs lasting over 5,000 hours. Flexible mounting options allow for installation on walls or ceilings, making them suitable for both single-family and multifamily residences. YFR offers a range of quartz infrared lamps designed for residential use, ensuring reliable performance and energy savings.

Businesses in the hospitality and service sectors rely on infrared heater bulbs to enhance guest comfort and reduce operational costs. Restaurants, clubs, hotels, and resorts use these heaters to warm outdoor patios, dining areas, and observation decks. The directional heat ensures that guests remain comfortable even when outdoor temperatures drop or wind conditions change. Commercial operators benefit from the energy efficiency of infrared systems, which consume about 30% less energy than traditional heating methods. This efficiency translates to lower utility bills and increased revenue by extending the outdoor season. Facilities such as country clubs, manufacturing plants, warehouses, and transportation hubs also use infrared heating to maintain comfortable environments for staff and visitors. YFR’s commercial-grade infrared lamps offer weatherproof designs and remote control features, supporting both indoor and outdoor applications.

Restaurants and hospitality venues use outdoor patio heaters to attract and retain customers.

Warehouses and manufacturing facilities install radiant heaters to improve workplace comfort and productivity.

Hotels and resorts deploy infrared systems in lobbies, lounges, and poolside areas for year-round comfort.

Stadiums and sports venues present unique challenges for comfort heating due to their large, open spaces and variable occupancy. Infrared heater bulbs provide an effective solution by delivering targeted, high-intensity heat to spectators and staff. Short-wave electric radiant heaters warm people directly, ensuring comfort even in partially enclosed or open-air environments. Stadium operators install these systems in seating areas, concourses, and VIP boxes to maintain a pleasant atmosphere during events. The technology’s rapid response and even heat distribution eliminate cold zones and support flexible, zoned heating strategies. YFR supplies robust, weather-resistant infrared lamps engineered for stadium use, offering reliable performance in demanding conditions. These solutions help venues increase attendance and enhance the overall fan experience, regardless of the weather.

Infrared comfort heating solutions from YFR combine energy efficiency, durability, and user satisfaction. They support a wide range of environments, from cozy homes to bustling stadiums, making them a preferred choice for modern comfort heating needs.

Comfort heating continues to evolve rapidly in 2025. Industry leaders observe several key trends shaping how homes, businesses, and public venues approach warmth and energy efficiency.

1. Smart Home Integration

Homeowners now expect heating systems to connect seamlessly with smart home platforms. Infrared heater bulbs work with voice assistants and mobile apps. Users schedule heating, monitor energy consumption, and adjust settings remotely. This integration increases convenience and helps families save on utility bills.

2. Zoned and Targeted Heating

Property owners seek greater control over indoor climates. Zoned heating allows users to warm specific rooms or areas without wasting energy on unused spaces. Infrared heater bulbs deliver direct, focused warmth. This approach reduces energy waste and creates personalized comfort zones in homes, restaurants, and stadiums.

3. Sustainability and Energy Efficiency

Environmental responsibility drives purchasing decisions. Consumers and businesses choose infrared heating for its low energy consumption and minimal emissions. Facilities report up to 30% lower energy use compared to traditional systems. Many organizations highlight these savings in sustainability reports and marketing materials.

4. Outdoor Comfort Expansion

Restaurants, hotels, and stadiums extend their usable space by installing weather-resistant infrared heaters. Patrons enjoy outdoor dining and events year-round. Stadium operators use high-output infrared lamps to keep spectators comfortable during cold weather games. This trend boosts revenue and enhances guest satisfaction.

5. Customization and Aesthetics

Design flexibility matters more than ever. Manufacturers offer infrared heater bulbs in various shapes, finishes, and mounting options. Businesses select fixtures that match their décor and branding. Homeowners choose discreet models that blend with interior design.

6. Safety and Compliance

Safety remains a top priority. Modern infrared heating systems include features such as tip-over protection, cool-touch surfaces, and automatic shutoff. Facility managers trust products that meet strict safety certifications. YFR’s solutions comply with industry standards, providing peace of mind for both residential and commercial users.

Note: YFR leads the market by offering a comprehensive range of comfort heating solutions. Their products combine smart controls, energy efficiency, and robust safety features. Customers benefit from American-made quality and responsive support.

Trend | Impact on Comfort Heating Users |

|---|---|

Smart Integration | Greater convenience, remote control |

Zoned Heating | Personalized comfort, energy savings |

Sustainability | Lower bills, reduced environmental impact |

Outdoor Comfort | Year-round use of patios and venues |

Customization | Enhanced aesthetics, tailored solutions |

Safety | Reliable operation, user protection |

Comfort heating will continue to advance as technology and consumer expectations grow. YFR’s commitment to innovation ensures that homes, businesses, and stadiums stay warm, efficient, and safe in every season.