Author: Site Editor Publish Time: 2025-09-16 Origin: Site

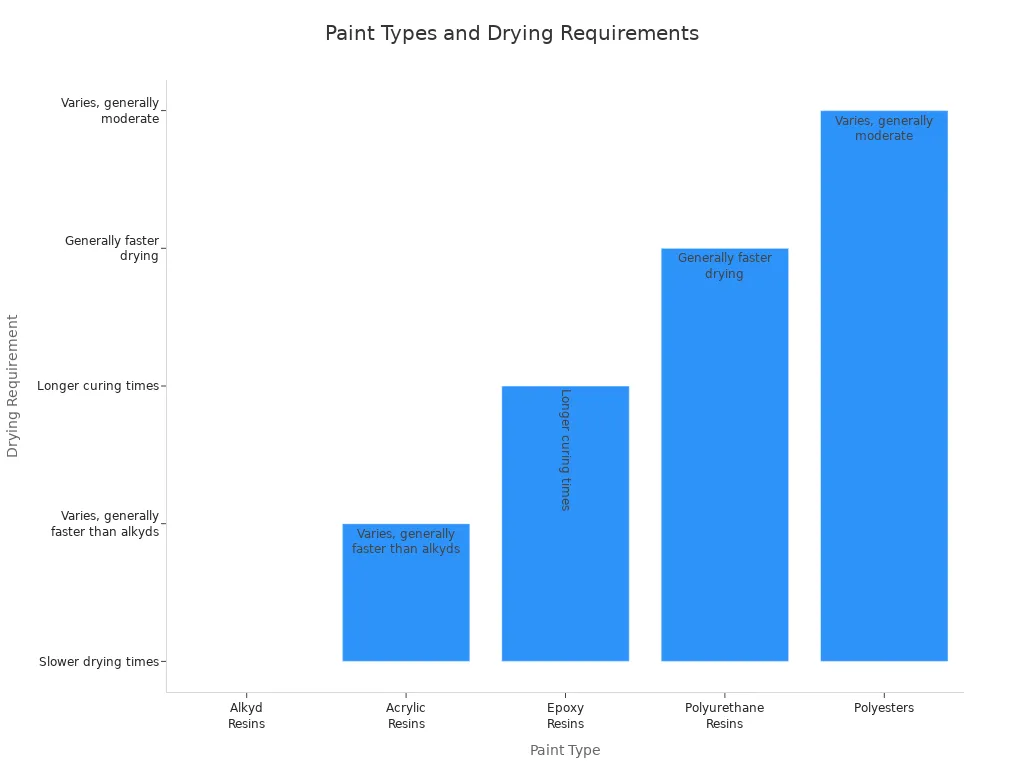

You achieve the best results in infrared paint drying when you match the wavelength to your paint type. Short wave infrared works well for water-based paints, while medium wave infrared suits solvent-based coatings. Selecting the right wavelength ensures efficient drying and a flawless finish. The table below highlights how different paints respond to drying methods in industrial and automotive settings.

Paint Type | Drying Requirements | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

Alkyd Resins | Slower drying times | Industrial and architectural coatings | Good flexibility and adhesion, less expensive | Less resistance to moisture and chemicals |

Acrylic Resins | Varies, generally faster than alkyds | Decorative coatings, clear finishes | Excellent UV stability, good color retention | Less chemical resistance than epoxies and polyurethanes |

Epoxy Resins | Longer curing times | Industrial flooring, protective coatings for metal | High durability, good chemical resistance | Limited UV resistance, can be brittle |

Polyurethane Resins | Generally faster drying | Automotive and truck body coatings | Excellent flexibility, impact resistance | Can be more expensive, some formulations have lower chemical resistance |

Polyesters | Varies, generally moderate | Outdoor products, marine equipment | Durability, weather resistance | Susceptibility to scratching, limited flexibility |

You can rely on Huai'an Infrared Heating Technology for advanced infrared lamps that match your specific drying needs. This guide provides practical advice, a quick reference, and step-by-step instructions to help you choose the right solution.

Match the infrared wavelength to your paint type for optimal drying results. Use medium wave for water-based paints and short wave for solvent-based coatings.

Consider the color of your paint. Dark colors absorb more infrared energy, leading to faster curing times compared to lighter colors.

Monitor environmental conditions like humidity and temperature. Aim for 65°F to 75°F (18°C to 24°C) for best results and keep humidity low to avoid defects.

Use a checklist to select the right infrared lamp. Identify your paint type, color, thickness, and substrate material to ensure proper curing.

Regularly maintain and calibrate your infrared lamps. Clean and replace lamps as needed to ensure consistent output and efficiency.

Avoid overheating by closely monitoring temperature settings. Use sensors to prevent damage to the paint and ensure a smooth finish.

Utilize advanced infrared lamps from Huai'an Infrared Heating Technology for energy efficiency and rapid curing, saving costs and time.

Always consult the paint manufacturer's guidelines for recommended drying methods and environmental conditions to achieve the best results.

You need to consider the absorption spectrum of water-based paints when selecting the best infrared wavelength for drying. Water absorbs medium-wave infrared radiation efficiently. This absorption leads to rapid heat conversion, which speeds up the drying process and saves energy. Medium-wave infrared lamps from Huai'an Infrared Heating Technology deliver consistent results for water-based coatings. You can achieve uniform drying without risking surface overheating. If you work with black paint, you will notice even greater efficiency, since black paint absorbs infrared energy more effectively than lighter colors. For most water-based applications, medium-wave infrared paint drying offers the best balance of speed and finish quality.

Tip: Always check the paint manufacturer’s recommendations for compatible drying methods. Matching the specific wavelengths to your paint type ensures optimal results.

You often use solvent-based paints in automotive and industrial settings. These paints respond best to short wave infrared energy. Short wave infrared penetrates deeper into the coating, curing from the inside out. This process prevents surface skinning and reduces the risk of trapped solvents. If you apply black paint, short wave infrared lamps from Huai'an Infrared Heating Technology can further enhance drying speed and uniformity. You should select short wave lamps for solvent-based coatings to maximize efficiency and achieve a flawless finish. Specific wavelengths matter because they determine how much energy the paint absorbs and how quickly it cures.

Specialty coatings require tailored solutions. You may work with epoxies, polyurethanes, or other advanced materials. These coatings often need precise control over the infrared wavelength and emitter type. Huai'an Infrared Heating Technology offers a range of products designed for these demanding applications. The table below highlights key options and compares them to industry alternatives:

Product Type | Key Features | Comparison to Alternatives |

|---|---|---|

Quartz IR Emitters | Rapid, targeted heat for industrial applications | More efficient and effective than traditional methods |

Ceramic Options | Versatile for broader environments | Offers flexibility not always available in competitors |

Metal-Sheathed IR | Suitable for challenging heating environments | Provides durability and reliability in demanding settings |

You should choose the emitter and wavelength based on the coating’s thickness, substrate, and color. Black paint, for example, absorbs infrared energy quickly, making it ideal for rapid curing with quartz IR emitters. Specialty coatings benefit from the advanced control and reliability offered by Huai'an Infrared Heating Technology’s infrared lamps.

Note: Always match the infrared lamp type and wavelength to your coating’s requirements for best results.

Paint Type | Recommended Infrared Wavelength | Huai'an Product Example |

|---|---|---|

Water-Based | Medium Wave | |

Solvent-Based | Short Wave | |

Specialty Coatings | Depends on formulation | Quartz IR, Ceramic, Metal-Sheathed IR |

Black Paint | Short or Medium Wave | Short/Medium Wave Infrared Lamp |

You can use this table as a quick reference when selecting the right infrared lamp for your paint drying needs.

You use infrared paint drying to speed up the curing of coatings by applying targeted radiant energy. Infrared waves penetrate the paint layer and transfer energy directly to the molecules inside. This process heats the paint from the inside out, which helps you achieve a uniform cure and reduces the risk of surface skinning or trapped solvents.

The depth of penetration depends on the wavelength you select. Short-wave infrared penetrates deeply, making it ideal for applications that require rapid and thorough curing. Medium-wave infrared strikes a balance, curing the coating efficiently without overheating the substrate. Long-wave infrared mainly warms the surface, so you use it for surface drying or thin layers. By choosing the right wavelength, you ensure that you cure the paint evenly and achieve a high-quality finish.

When you use advanced infrared lamps from Huai'an Infrared Heating Technology, you gain several operational advantages:

Energy efficiency with conversion rates exceeding 96%.

Cost savings between 20% and 50% compared to traditional methods.

Rapid curing times, reducing curing duration by 50% or more.

Focused infrared energy that heats only the product, enhancing efficiency.

Superior quality with precise control of curing, reducing defects.

Blazing speed in curing times, allowing faster product turnover.

Targeted energy application that minimizes unnecessary heating of surrounding areas.

Consistent quality finishes due to controlled wavelength curing.

Dramatic reduction in curing times, enhancing productivity.

Focused energy application leading to lower operational costs.

Precise control ensuring high-quality finishes.

You also benefit from documented energy savings when you switch to infrared paint drying:

Carbon infrared emitters can require up to 30% less energy for the drying process compared to conventional short-wave infrared emitters.

A specific case showed a 93% energy savings when switching to moisture accelerated curing with TEKNODUR COMBI 3560.

You can rely on these benefits to improve your workflow, reduce expenses, and deliver consistent results. Infrared paint drying helps you achieve a high level of quality while keeping your curing time to a minimum.

You must follow safety standards and best practices to avoid risks during curing paint with infrared technology. Proper setup and maintenance ensure safe and effective operation. The table below outlines key safety guidelines:

Safety Standard/Guideline | Description |

|---|---|

Temperature Settings | Set temperatures according to paint manufacturer’s recommendations to avoid overheating. |

Airflow Management | Ensure ventilation systems are clear for uniform drying conditions. |

Lamp Maintenance | Regularly clean and replace lamps for consistent output and efficiency. |

Protective Equipment | Use appropriate PPE when working near UV curing machines. |

Regular Calibration | Periodic calibration of sensors and control systems ensures optimal performance. |

Fire Safety | Maintain clear zones around equipment to prevent fire hazards from flammable solvents. |

Emergency Stop | Operators should know emergency shutdown procedures for handling operational anomalies. |

You should always monitor the curing process and adjust settings as needed. Overheating, poor airflow, or lack of maintenance can lead to defects or safety hazards. By following these guidelines, you ensure safe, efficient, and high-quality curing every time.

You need to understand how the operating wavelength of infrared curing technology affects the speed and quality of curing paint. Each paint type absorbs energy differently, so matching the wavelength to the paint’s absorption properties leads to faster drying and better quality finishes. When you use infrared paint drying, you can select from three main categories in the infrared range:

Short-wave (near-infrared): 0.7 to 1.5 µm

Medium-wave (mid-infrared): 1.5 to 3 µm

Long-wave (far-infrared): 3 to 1,000 µm

Short-wave infrared curing technology penetrates deeply, making it ideal for solvent-based coatings and thick layers. Medium-wave infrared curing technology works best for water-based paints and infrared absorbing coatings, providing balanced heat without overheating the substrate. Long-wave infrared curing technology suits surface-level applications and thin coatings. By adjusting the infrared curing technology to match the paint’s absorption spectrum, you improve curing speed and maintain high quality. This process also keeps surrounding materials cooler, which boosts production efficiency.

Tip: Always check the paint’s technical data sheet for recommended infrared range before starting the curing process.

You can optimize curing by adjusting the power output and emitter shape in your infrared curing technology setup. Higher power settings increase curing speed, but you must avoid overheating to protect the paint’s quality. You should select emitter shapes that match the surface area and geometry of your workpiece. For example, twin tube lamps provide uniform coverage for large panels, while spot emitters target small or complex areas.

Huai'an Infrared Heating Technology offers mobile infrared curing systems and a wide range of infrared lamps with advanced features. You benefit from energy conversion rates up to 96%, which means more efficient curing and lower operational costs. The products carry CE and TUV certifications, so you can trust their safety and reliability. You can choose from quartz, ceramic, or metal-sheathed emitters to suit your specific curing paint needs.

Feature | Benefit for Curing Paint |

|---|---|

Adjustable Power Output | Controls curing speed and quality |

Multiple Emitter Shapes | Matches workpiece geometry |

High Energy Conversion | Reduces energy costs |

Certified Products | Ensures safety and reliability |

When you use infrared curing technology with the right power and shape adjustments, you achieve consistent curing results and superior quality finishes. You can rely on these systems for efficient, safe, and repeatable curing in any industrial setting.

You need to pay close attention to the color of paint when planning the curing process. The pigments and binders in paint films control how much energy the surface absorbs or reflects. Dark colors, such as black, absorb more energy and speed up curing. Light colors, especially those with reflective pigments, slow down the process because they reflect more energy away from the surface.

Paint manufacturers use special pigment blends to manage how paint interacts with energy. Some paints include reflective flake pigments and color-scattering co-pigments. These ingredients help regulate thermal properties and improve energy efficiency during curing. When you use paints with high spectral selectivity, you can control reflectance in different regions, including thermal infrared. This control is important for achieving consistent curing results.

You will notice that the interaction between different spectral bands in the paint enhances thermal performance. By modulating spectral selectivity, you can reach high reflectivity in the near-infrared region. This strategy supports sustainable building practices and helps you save energy during curing.

Many modern coatings use Arctic IR reflective pigment technology. These paints absorb visible light but reflect infrared energy, which reduces heat build-up. Higher Total Solar Reflectance (TSR) means less energy absorption and cooler surfaces. You see these coatings in cool roofs, pavement, and energy-efficient facades. When you select paints with these features, you improve curing control and reduce the risk of overheating.

Consider these points when choosing paint color for curing:

Dark colors cure faster because they absorb more energy.

Light colors with reflective pigments require longer curing times.

Specialty coatings with high TSR keep surfaces cooler and need careful curing management.

Pigment technology can help you achieve uniform curing and energy savings.

Tip: Always check the technical data sheet for pigment composition and recommended curing settings. This step ensures you match the curing process to the paint’s color and thermal properties.

You can optimize curing by understanding how color and pigment technology affect energy absorption. This knowledge helps you achieve high-quality finishes and efficient production.

You must pay close attention to your environment when curing paint with infrared technology. Environmental conditions play a critical role in the drying process and can influence the final quality of your finish. Two main factors—humidity and ambient temperature—stand out as the most significant.

Environmental Factor | Impact on Infrared Paint Drying Performance |

|---|---|

Humidity | High humidity hinders cooling performance and affects IR emissivity, making subambient cooling challenging. |

Ambient Temperature | Affects application and curing of paint; optimal temperatures are crucial for proper adhesion and drying. |

Humidity levels in your workspace can change how efficiently infrared energy dries paint. High humidity slows down evaporation, which can lead to longer drying times and uneven finishes. When moisture lingers in the air, it interferes with the paint’s ability to cure properly. You may notice that surfaces remain tacky or develop defects if humidity stays high during the process. For best results, keep humidity as low as possible, especially when working with water-based paints.

Ambient temperature also has a direct impact on paint curing. The temperature in your workspace determines how well the paint flows, adheres, and dries. You should aim for a temperature range between 65°F and 75°F (18°C to 24°C) for optimal performance. If the temperature drops too low, paint viscosity increases. This makes application more difficult and can result in poor adhesion. On the other hand, high temperatures may cause the paint to dry too quickly on the surface, trapping solvents or moisture underneath.

Ambient temperature affects paint flow, adhesion, and curing.

Recommended temperature ranges for optimal performance are 65-75°F (18-24°C).

Low temperatures can lead to increased viscosity and poor adhesion.

You should monitor both humidity and temperature before and during the curing process. Use reliable sensors or meters to track these conditions. If you notice that the environment falls outside the recommended range, adjust your infrared lamp settings or wait until conditions improve. Many professionals use dehumidifiers or climate control systems to maintain stable conditions in their paint booths.

Tip: Always check the paint manufacturer’s guidelines for recommended environmental conditions. Following these recommendations helps you achieve a flawless finish and reduces the risk of defects.

By controlling your environment, you ensure that your infrared paint drying process delivers consistent, high-quality results. You protect your investment in both materials and equipment, and you maintain a professional standard in every project.

You need a clear process to select the best infrared wavelength and lamp for your paint drying project. Use this checklist to guide your decision. Each step helps you match your paint type, environment, and equipment for optimal results.

Identify Your Paint Type

Water-based, solvent-based, or specialty coating?

Check the technical data sheet for details.

Determine Paint Color

Is the paint dark or light?

Dark colors absorb more infrared energy.

Measure Paint Thickness

Thin or thick layers?

Thicker coatings may need deeper penetration.

Assess Substrate Material

Metal, plastic, wood, or composite?

Some substrates require gentle heating.

Review Environmental Conditions

What is the humidity and temperature in your workspace?

Stable conditions improve drying quality.

Medium wave for water-based paints.

Specialty coatings may need tailored solutions.

Choose Lamp Type and Shape

Twin tube, spot, or panel emitter?

Match lamp shape to your workpiece.

Check Power Output

Does the lamp provide enough energy for your application?

Adjustable power settings offer flexibility.

Verify Certifications

Look for CE and TUV marks.

Huai'an Infrared Heating Technology products meet these standards.

Plan for Safety

Set up proper ventilation.

Use protective equipment as needed.

Tip: Keep this checklist handy during every project. You reduce mistakes and ensure consistent, high-quality results.

You can follow this simple flowchart to select the right infrared lamp and wavelength for your paint drying needs. Each step leads you to the best choice for your specific situation.

graph TD

A[Start: Identify Paint Type] --> B{Water-Based?}

B -- Yes --> C[Select Medium Wave Infrared Lamp]

B -- No --> D{Solvent-Based?}

D -- Yes --> E[Select Short Wave Infrared Lamp]

D -- No --> F{Specialty Coating?}

F -- Yes --> G[Consult Technical Data Sheet]

G --> H[Choose Quartz, Ceramic, or Metal-Sheathed IR]

F -- No --> I[Contact Huai'an Infrared Heating Technology for Guidance]

C --> J[Assess Paint Color]

E --> J

H --> J

J --> K{Dark Color?}

K -- Yes --> L[Proceed: Enhanced Absorption]

K -- No --> M[Adjust Curing Time]

L --> N[Check Thickness & Substrate]

M --> N

N --> O[Review Environment]

O --> P[Set Power & Safety]

P --> Q[Begin Curing Process]

Note: If you face uncertainty at any step, reach out to Huai'an Infrared Heating Technology for expert advice. You ensure the best outcome by following a proven selection process.

You must avoid overheating during curing. Excessive heat can damage paint layers, cause bubbling, or lead to discoloration. When you set the temperature too high, you risk burning the surface or causing uneven curing. You should always monitor the temperature closely. Use sensors or infrared thermometers to check the surface regularly. If you notice any signs of blistering or color change, reduce the heat immediately.

Overheating often happens when you use high power settings without considering the paint type or thickness. You need to adjust the curing process for each project. Thin coatings require less energy, while thick layers need more controlled heat. You should follow the paint manufacturer’s guidelines for recommended curing temperatures. This step helps you maintain a smooth finish and prevents costly mistakes.

Tip: Set up a timer and temperature alarm for each curing session. This practice helps you avoid overheating and ensures consistent results.

Selecting the wrong wavelength can lead to poor curing results. Each paint type absorbs energy differently. If you use the incorrect wavelength, you may experience slow drying, surface skinning, or incomplete curing. Water-based paints respond best to medium wave energy. Solvent-based coatings require short wave energy for deep penetration. Specialty coatings may need a tailored approach.

You should always match the wavelength to the paint’s absorption spectrum. Review the technical data sheet before starting the curing process. If you notice uneven drying or defects, check your wavelength settings. Adjust the lamp or switch to a different product if needed. Proper wavelength selection ensures efficient curing and a flawless finish.

Paint Type | Best Wavelength for Curing |

|---|---|

Water-Based | Medium Wave |

Solvent-Based | Short Wave |

Specialty Coatings | Depends on formulation |

Note: Consult with experts at Huai'an Infrared Heating Technology if you have questions about wavelength selection.

You must consider the substrate before curing paint. Different materials react to heat in unique ways. Metal substrates can handle higher temperatures, while plastics or composites may warp or melt if exposed to excessive heat. If you ignore the substrate, you risk damaging the workpiece and ruining the finish.

You should assess the substrate’s heat tolerance before starting the curing process. Adjust the power output and lamp distance to protect sensitive materials. For example, use lower settings for plastic parts and higher settings for metal panels. Always test a small area first to check for any adverse reactions.

Reminder: Substrate compatibility is essential for successful curing. Take time to evaluate the material and adjust your process accordingly.

You might overlook the environment when you focus on paint type and equipment. This mistake can lead to poor results and wasted materials. The environment plays a critical role in infrared paint drying. You need to control humidity, temperature, and airflow to achieve a flawless finish.

High humidity slows down the drying process. Moisture in the air prevents paint from curing evenly. You may see tacky surfaces or bubbles if you ignore humidity. Low humidity helps paint dry faster and more consistently. You should use a hygrometer to measure humidity before starting the curing process.

Temperature affects how paint reacts to infrared energy. If the workspace is too cold, paint becomes thick and hard to apply. Low temperatures slow down curing and can cause poor adhesion. High temperatures speed up drying but may trap solvents or moisture under the surface. You should keep the workspace between 65°F and 75°F (18°C to 24°C) for best results.

Airflow also matters. Poor ventilation leads to uneven drying and can cause defects. You need to make sure air moves freely around the workpiece. Good airflow helps remove moisture and solvents from the paint layer. You can use fans or ventilation systems to improve air movement.

Tip: Always check the paint manufacturer’s guidelines for recommended environmental conditions. Following these instructions helps you avoid costly mistakes.

Here is a quick checklist to help you manage your environment:

Measure humidity with a reliable meter.

Monitor workspace temperature before and during curing.

Use fans or ventilation systems to maintain airflow.

Adjust infrared lamp settings based on environmental readings.

Record conditions for each project to track results.

Environmental Factor | What Happens If You Skip It | How to Fix It |

|---|---|---|

Humidity | Slow drying, tacky finish | Use dehumidifiers, monitor |

Temperature | Poor adhesion, defects | Heat or cool workspace |

Airflow | Uneven curing, bubbles | Improve ventilation |

You should never skip environmental checks. You protect your work and ensure consistent quality by controlling these factors. Huai'an Infrared Heating Technology recommends regular monitoring and adjustment for every project. You set yourself up for success when you create the right environment for infrared paint drying.

Ignoring the environment can ruin your finish and waste time. You need to treat environmental control as part of your standard process. You will see better results, fewer defects, and higher efficiency when you pay attention to humidity, temperature, and airflow.

Reminder: The right environment makes all the difference. You achieve professional results when you combine proper equipment with careful environmental management.

You improve results when you choose the right wavelength for infrared paint drying. Matching the wavelength to your paint type ensures fast curing and a flawless finish. Use the quick guide and checklist to streamline your curing process. Huai'an Infrared Heating Technology provides reliable infrared lamps for every curing need. For your next project, review the FAQs and reach out for expert advice. You achieve consistent curing and professional results with the right tools and knowledge.

Medium wave infrared suits water-based paints. You achieve fast, uniform drying without overheating the surface. Huai'an Infrared Heating Technology offers medium wave lamps designed for these applications.

Short wave infrared works best for solvent-based coatings. You get deep penetration and quick curing. This method prevents surface skinning and reduces trapped solvents.

You should check the technical data sheet for your coating. Match the lamp type and wavelength to the coating’s thickness, color, and substrate. Huai'an Infrared Heating Technology provides quartz, ceramic, and metal-sheathed options.

Dark colors absorb more infrared energy. You see faster curing with black or deep shades. Light colors reflect energy, so you need longer curing times or higher power settings.

You get products certified with CE and TUV marks. These certifications ensure safety, reliability, and compliance with industry standards.

Monitor temperature with sensors or infrared thermometers. Adjust power settings based on paint type and thickness. Follow manufacturer guidelines for curing temperatures.

High humidity slows drying and can cause defects. You should control humidity with dehumidifiers or climate systems. Always check workspace conditions before starting the curing process.

IR Paint Drying in 2025: The Ultimate Beginner's Guide To Faster, Eco-Friendly Curing

Infrared Paint Drying: How It Speeds Up Production Without Sacrificing Finish Quality

Infrared Powder Coating Lamps: Pros, Cons, and Key Benefits Explained

How Infrared Heaters Help You Achieve a Smooth, Professional Paint Finish