Author: Site Editor Publish Time: 2025-09-08 Origin: Site

When I search for the best infrared lamp, I always consider my exact heating needs. The answer to “Which infrared lamp is best for me?” depends on how much heat and comfort I want. Recent data shows the global NDIR Sensor Lamps market continues to grow:

USD 8.45 Million in 2024

USD 8.93 Million projected for 2025

5.6% CAGR through 2034

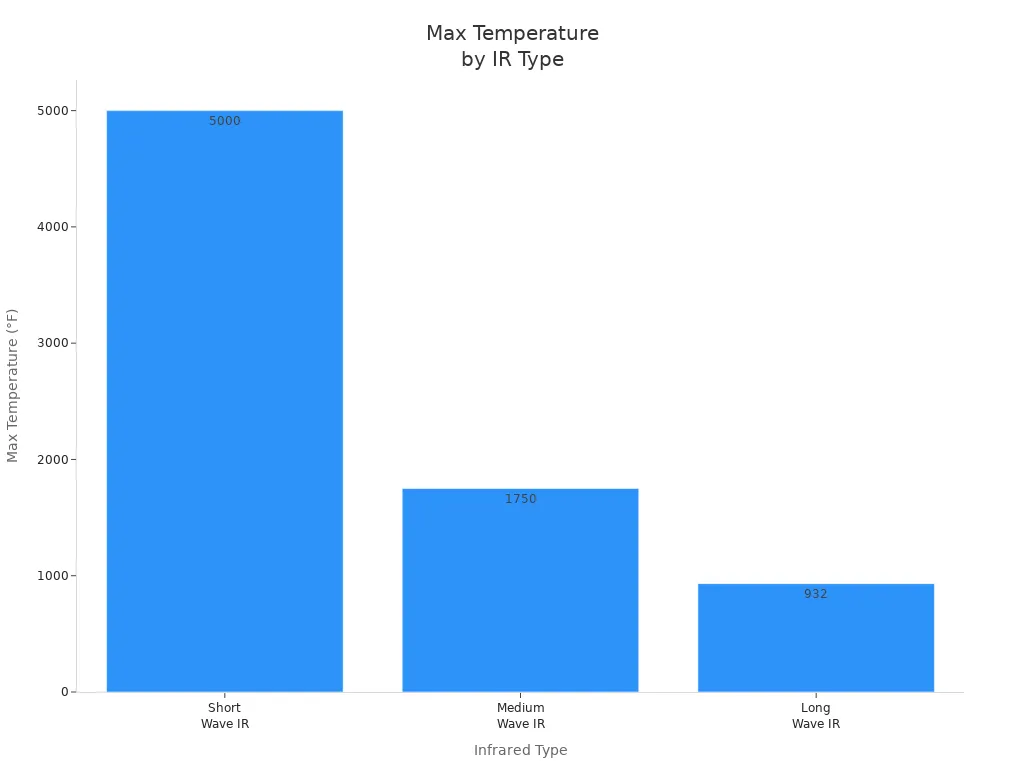

The main differences between Shortwave infrared lamps, mediumwave, and longwave models come down to their heat intensity and application:

IR Type | Wavelength (microns) | Max Temp | Primary Use |

|---|---|---|---|

Short Wave IR | 0.76 – 2.0 | Up to 5000°F | High-intensity industrial heating |

Medium Wave IR | 1.4 – 3.0 | Up to 1750°F | Drying, plastics, textiles |

Long Wave IR | Above 3.0 | 100–500°C | Comfort and space heating |

Identify your heating needs before choosing an infrared lamp. Different types serve various purposes.

Shortwave infrared lamps provide rapid, intense heat, ideal for industrial tasks like paint curing and drying.

Mediumwave lamps balance comfort and efficiency, making them suitable for textile and glass manufacturing.

Longwave infrared lamps offer gentle warmth, perfect for residential and hospitality settings where comfort is key.

Consider energy efficiency when selecting a lamp. Shortwave models are the most efficient, while longwave lamps consume more energy.

Regular maintenance is crucial for all infrared lamps. Clean surfaces and check connections to ensure safe operation.

Use a decision checklist to guide your selection process. Assess treatment goals, space constraints, and usage frequency.

Always follow safety guidelines and manufacturer instructions to prevent accidents and ensure optimal performance.

When I evaluate shortwave infrared lamps, I focus on their ability to deliver intense heat quickly. These lamps operate at high power outputs, typically ranging from 2100W to 3300W. I often see a 2200W lamp reach surface temperatures of about 350°C, while a 3300W model can accelerate paint curing by penetrating deep into the paint layer. Their superior heating efficiency stands out compared to traditional far-wave infrared options.

Key Features:

Rapid response time and immediate heat delivery.

High-intensity output, ideal for demanding environments.

Power output: 2100W to 3300W.

Superior efficiency for industrial applications.

Best-Use Scenarios:

Industrial inspection, where I need to identify subsurface defects in manufacturing.

Crop-health monitoring, using advanced SWIR systems in agriculture.

Defense night-vision systems, which benefit from modernized technology.

Plastic recycling, where regulations require precise sorting of polymers.

Use Case | Description |

|---|---|

Industrial Inspection | Identifies subsurface defects in manufacturing processes. |

Crop-Health Monitoring | Monitors agricultural health with drones and ground rovers. |

Defense Night-Vision | Enhances military capabilities with upgraded night-vision systems. |

Plastic Recycling | Distinguishes polymer grades in waste for improved recycling. |

Mediumwave lamps offer a balanced approach between intensity and comfort. I notice that these lamps respond quickly, reaching 90% output within three seconds and dissipating 90% of their energy within five seconds. The average lifespan is about 5000 hours, which makes them cost-effective for many applications. I often choose mediumwave lamps for their versatility and reliability.

Key Features:

Wavelengths: Short (1.15 µm) and medium (1.8 µm).

Heat flux densities: 100 watt/linear inch or 200 watt/inch.

Length range: 2 to 38 inches.

Average lamp life: 5000 hours.

Best-Use Scenarios:

Glass manufacturing, where I see production efficiency improve by at least 50% and energy consumption drop by 35%.

Textile printing and leather curing, which require efficient drying processes.

3D printing, where interlayer strength and product quality increase.

Tip: I recommend mediumwave lamps for industries that demand both speed and energy savings, especially when product quality matters.

Longwave lamps provide gentle, comfortable warmth. I find these lamps most effective in commercial and residential settings, where comfort and safety take priority over intense heat. They excel in environments where people gather and need consistent, mild warmth.

Key Features:

Lower maximum temperatures, typically between 100°C and 500°C.

Designed for comfort heating rather than rapid or deep penetration.

Ideal for weatherproof and outdoor applications.

Best-Use Scenarios:

Patio and terrace heaters, which keep outdoor spaces warm.

Outdoor seating or dining areas, enhancing comfort for guests.

Commercial or hospitality heating systems, providing reliable warmth in all weather.

Application Type | Description |

|---|---|

Patio and terrace heaters | Provides warmth in outdoor spaces. |

Outdoor seating or dining area warmers | Enhances comfort for diners in outdoor settings. |

Commercial or hospitality heating | Suitable for businesses needing weatherproof heating solutions. |

Note: I always recommend longwave lamps when comfort and safety are the top priorities, especially in public or residential spaces.

I rely on shortwave infrared lamps when I need rapid, high-intensity heat. These lamps emit radiation in the 0.76 to 2.0 micron range. The shortwave infrared heater uses a tungsten filament inside a quartz tube. When I power the lamp, the filament heats up quickly and produces strong infrared radiation. The energy penetrates surfaces deeply, making it ideal for industrial tasks. I always check the lamp structure before installation. A single quartz tube design offers better lead spacing, which improves safety. Double quartz tubes require careful bore spacing to prevent electrical hazards.

Tip: I always consider range requirements, output power, and beam angle before choosing a shortwave lamp. For high-intensity applications, I select a narrow beam angle to focus the heat.

Shortwave lamps excel in environments where speed and intensity matter. I use them for:

Paint curing in automotive shops

Industrial drying processes

Subsurface defect detection in manufacturing

Plastic sorting and recycling

I recommend shortwave infrared lamps for tasks that demand immediate, deep heat penetration. When I need covert illumination, I choose a 940 nm wavelength for invisible radiation. For visible glow and greater intensity, I select 850 nm.

Mediumwave lamps operate in the 1.4 to 3.0 micron range. I notice these lamps use a filament that heats up more slowly than shortwave models. The radiation produced is less intense but more comfortable. Mediumwave lamps reach 90% output within three seconds. The heat dissipates quickly, which helps with energy efficiency. I always check the voltage selection and electrode surface treatment. A 110V power supply reduces electric field strength. Polished electrodes eliminate burrs, and I maintain a minimum spacing of 10mm for safety.

I use mediumwave lamps for applications that require balanced heat and comfort. These include:

Textile and leather drying

Glass manufacturing

3D printing processes

Mediumwave lamps provide reliable performance and energy savings. I recommend them for industries where product quality and efficiency are priorities.

Longwave lamps emit radiation above 3.0 microns. I find these lamps produce gentle warmth, making them perfect for comfort heating. The filament heats up slowly, and the lamp maintains lower temperatures. Longwave lamps do not penetrate surfaces deeply. Instead, they warm the air and nearby objects. I prefer these lamps for weatherproof designs in outdoor settings.

Longwave lamps suit environments where comfort and safety matter most. I use them for:

Patio and terrace heating

Outdoor dining areas

Commercial hospitality spaces

I recommend longwave lamps for public and residential spaces. The gentle heat creates a pleasant atmosphere without the risk of overheating.

When I need rapid heat delivery, I always turn to shortwave infrared lamps. These lamps excel at heating surfaces almost instantly. In my experience, a shortwave infrared heater can raise the temperature of thin films or coatings in seconds. This immediate response proves essential for industrial processes such as paint curing, where production speed and quality matter.

Shortwave infrared heaters transfer energy directly to the surface, minimizing heat loss and maximizing efficiency. I rely on their strong penetration to maintain uniform temperature, which ensures consistent results in manufacturing. The table below highlights the main advantages of using shortwave infrared lamps for fast heating:

Advantage | Description |

|---|---|

Rapid Surface Heating | Heats thin film surfaces quickly, improving crystallization rate and production efficiency. |

Efficient Energy Transfer | Delivers energy directly to the surface, enhancing energy efficiency. |

Uniform Temperature | Maintains temperature uniformity, ensuring consistent quality during curing. |

I recommend shortwave infrared lamps for applications that demand immediate heat, such as industrial drying, paint curing, and rapid thermal processing. These lamps meet the needs of manufacturers who prioritize speed and precision.

Tip: For home use, I suggest choosing shortwave infrared heaters for garages or workshops where fast heat is necessary.

When comfort is my priority, I select mediumwave and longwave infrared lamps. These lamps provide gentle warmth, making them ideal for comfort heating in residential and commercial spaces. I notice that mediumwave lamps offer a balanced heat output, which creates a pleasant environment without overheating. Longwave lamps deliver even softer heat, perfect for patios, terraces, and hospitality areas.

I use comfort heating solutions in restaurants, outdoor seating areas, and living rooms. The mild radiation from these lamps warms people and objects directly, rather than just the air. This approach improves energy efficiency and enhances comfort for guests and residents.

Mediumwave lamps suit indoor spaces where balanced heat and comfort matter.

Longwave lamps excel in outdoor settings, providing reliable warmth in all weather conditions.

Note: I always recommend comfort heating systems for environments where people gather and comfort is essential.

For applications that require deep heat penetration, I rely on shortwave and mediumwave infrared lamps. Scientific studies show that shortwave infrared radiation penetrates tissue and materials more effectively than other types. SWIR imaging reduces light attenuation and targets absorption peaks related to water and lipids. This capability allows me to assess burn wounds and evaluate tissue health with greater accuracy.

Mediumwave lamps also offer significant depth, aiding in muscle relaxation and improving circulation. Far infrared radiation penetrates up to 1.5 inches below the skin, making it ideal for therapeutic uses and industrial curing processes. I use these lamps for deep tissue therapy, muscle recovery, and curing thick coatings in manufacturing.

Key Findings | Implications |

|---|---|

SWIR imaging reduces light attenuation and targets water/lipid absorption. | Enables deep tissue penetration for medical and industrial uses. |

Water absorption at 1940 nm is higher than at 970 nm. | Allows mapping of tissue water content for health assessments. |

SWIR wavelengths analyze both superficial and deeper dermal layers. | Supports comprehensive evaluation of tissue and material quality. |

Near-infrared lamps affect the skin’s surface and provide relief for minor pain.

Mid-infrared lamps penetrate deeper, supporting muscle relaxation and circulation.

Far infrared lamps reach the deepest layers, addressing muscle and joint needs.

I recommend shortwave infrared lamps for industrial curing and medical imaging. Mediumwave and longwave lamps serve well in therapeutic and comfort heating applications.

I always prioritize energy efficiency when selecting infrared lamps for any heating application. The right choice can lower operational costs and reduce environmental impact. I compare shortwave, mediumwave, and longwave infrared lamps based on their energy efficiency ratings and practical performance.

Type of Infrared Lamp | Energy Efficiency Rating | Description |

|---|---|---|

Shortwave | Up to 90% | Most efficient, warms instantly, ideal for outdoor use. |

Mediumwave | Moderate efficiency | Balances performance without harsh glow. |

Longwave | About 40% | Least efficient, suitable for indoor spaces. |

Shortwave infrared lamps deliver the highest efficiency. I use them in industrial settings where rapid heat and minimal energy loss are essential. These lamps convert most of their electrical input into usable heat, which makes them ideal for large outdoor areas and manufacturing processes. I notice that shortwave models warm surfaces instantly, reducing the time and energy needed for effective heating.

Mediumwave lamps offer moderate efficiency. I recommend them for environments that require balanced heat output without the harsh glare of shortwave units. Mediumwave lamps work well in textile factories and glass production lines. Their ability to provide consistent heating while conserving energy makes them a reliable choice for many commercial applications.

Longwave infrared lamps have the lowest efficiency rating. I use these lamps in indoor spaces where comfort heating is the main goal. Although they convert less energy into heat, longwave lamps create a gentle and pleasant atmosphere. I find them suitable for homes, restaurants, and hospitality venues where comfort takes priority over rapid heating.

Tip: I always assess the size of the space and the desired heating intensity before choosing an infrared lamp. For outdoor or industrial use, I select shortwave lamps to maximize energy savings. For indoor comfort heating, I prefer longwave models despite their lower efficiency.

Safety remains my top concern when installing and operating infrared lamps. I follow strict guidelines and standards to protect users and property. In 2025, several certifications and standards govern the safe use of infrared heating devices:

IEC 60825-1: This standard classifies and regulates the safety of infrared lasers, focusing on maximum permissible exposure.

ANSI Z136.1: This standard outlines safe operational procedures for infrared-emitting devices, emphasizing wavelength and power requirements.

I always check these certifications before purchasing any infrared lamp. Compliance ensures that the device meets industry safety benchmarks and reduces the risk of accidents.

Infrared lamps present different safety concerns depending on their type. I use the following table to evaluate risks and implement preventive measures:

Infrared Type | Safety Concerns |

|---|---|

Short Wave | Intense heat can cause burns; glare may be uncomfortable; requires careful installation to avoid overheating materials. |

Medium Wave | Lower surface temperatures reduce risk; still requires clearance from flammable materials. |

Long Wave | Minimal risk of overheating; comfortable for prolonged exposure; operates at lower temperatures, but installation guidelines must be followed. |

Shortwave infrared lamps generate intense heat. I always install these units with proper shielding and maintain safe distances from flammable materials. Glare can be an issue, so I use protective covers or diffusers to minimize discomfort.

Mediumwave lamps operate at lower surface temperatures. I still ensure adequate clearance and follow manufacturer instructions to prevent accidental contact or fire hazards.

Longwave lamps pose minimal risk. Their gentle heat and lower operating temperatures make them safe for prolonged exposure. I always follow installation guidelines to guarantee safe operation in public and residential spaces.

Note: I recommend regular maintenance and safety checks for all infrared heating systems. Proper installation and adherence to safety standards protect users and extend the lifespan of the equipment.

When I evaluate shortwave infrared lamps, I notice their ability to deliver deep heat penetration. These lamps work well for muscle and joint pain relief. I often use them in physical therapy clinics because they reach deeper tissue layers. Their rapid heating performance saves time in industrial settings. I see them accelerate paint curing and drying processes. The immediate response and high intensity make them ideal for manufacturing environments. I also appreciate their effectiveness in medical imaging and diagnostics.

Deep tissue penetration

Fast heat delivery

Effective for muscle and joint pain

Useful in industrial and medical applications

Despite their strengths, shortwave infrared lamps present some challenges. If I use them improperly, they may cause discomfort or even burns. The intense heat requires careful installation and monitoring. I always advise users to maintain safe distances and use protective covers. These lamps can produce glare, which sometimes leads to eye strain. Their high energy consumption increases operational costs in large-scale applications.

Note: I recommend regular safety checks and proper training for anyone using shortwave infrared lamps in clinical or industrial settings.

Mediumwave lamps offer a balanced approach to heating. I find them especially useful for promoting blood circulation and supporting detoxification. Their moderate penetration suits therapeutic treatments and industrial drying. These lamps respond quickly, reaching optimal output in seconds. I use them in textile factories and glass manufacturing because they improve efficiency and product quality. Their energy consumption remains reasonable, which helps control costs.

Promotes blood circulation

Supports detoxification

Quick response time

Balanced heat output

Mediumwave lamps do not penetrate as deeply as shortwave models. I notice their effectiveness drops for treatments that require reaching deeper tissue layers. In industrial settings, they may not deliver the same rapid results as shortwave units. Their versatility sometimes means they lack specialization for certain tasks. I always assess the specific requirements before choosing mediumwave lamps for a project.

Tip: I recommend mediumwave lamps for environments where balanced heat and comfort matter more than deep penetration.

Longwave lamps excel in providing gentle, superficial warmth. I use them for skin cleansing and comfort heating in homes and hospitality venues. Their low operating temperature makes them safe for prolonged exposure. I rarely encounter overheating issues with these lamps. They create a pleasant atmosphere in outdoor dining areas and patios. Their design suits weatherproof applications, which increases their versatility.

Ideal for superficial treatments

Safe for extended use

Suitable for comfort heating

Minimal risk of overheating

Longwave lamps have shallow penetration. I find them less effective for deeper therapeutic treatments or industrial curing. Their energy efficiency lags behind shortwave and mediumwave options. In large spaces, they may struggle to maintain consistent warmth. I always consider the environment and heating needs before recommending longwave lamps.

Type of Infrared Lamp | Advantages | Disadvantages |

|---|---|---|

Shortwave (IR-A) | Deep penetration, effective for muscle/joint pain | May cause discomfort if used improperly |

Mediumwave (IR-B) | Promotes blood circulation, supports detoxification | Less penetration than shortwave |

Longwave (IR-C) | Ideal for superficial treatments, skin cleansing | Shallow penetration, less effective for deep issues |

When I evaluate infrared lamps, I always start by comparing the initial investment. Shortwave infrared lamps usually offer the lowest upfront cost. Manufacturers design these units for rapid heating, which keeps the price competitive. Mediumwave lamps fall into a moderate price range. Their balanced performance and versatility justify the extra expense. Longwave infrared lamps often require a higher initial investment. These models feature advanced weatherproofing and comfort-focused designs, which increase their price.

Type | Initial Cost | Lifespan (hours) | Replacement Cost Impact |

|---|---|---|---|

Short Wave | Lower | 5,000 - 7,000 | High |

Medium Wave | Moderate | 7,000 - 10,000 | Moderate |

Long Wave | Higher | 20,000+ | Low |

I always advise clients to consider both the upfront cost and the expected lifespan. A higher initial price for longwave lamps often pays off over time due to their extended service life.

Operating costs play a major role in my decision-making process. Shortwave infrared lamps consume more energy because they deliver intense heat quickly. I notice that these units require frequent replacement, which increases the total running cost. Mediumwave lamps strike a balance between energy consumption and longevity. Their moderate power draw and longer lifespan help control expenses. Longwave infrared lamps stand out for their low running costs. Their energy-efficient design and long service life minimize the need for replacements.

Tip: I always calculate the total cost of ownership before making a purchase. Factoring in energy usage and replacement frequency helps me avoid unexpected expenses.

Here is a quick summary of typical running costs based on average usage:

Shortwave: High energy consumption, frequent replacements, higher overall running cost.

Mediumwave: Moderate energy use, reasonable replacement intervals, balanced running cost.

Longwave: Low energy use, rare replacements, lowest running cost.

Maintenance requirements vary by lamp type. Shortwave infrared lamps demand regular inspection and cleaning. Their high operating temperatures can cause wear and tear, so I schedule frequent checks to prevent failures. Mediumwave lamps need less attention. I clean the lamp surfaces and check connections every few months. Longwave infrared lamps require minimal maintenance. Their robust construction and lower operating temperatures reduce the risk of breakdowns.

I replace shortwave lamps more often due to their shorter lifespan.

Mediumwave lamps last longer, but I still monitor them for signs of aging.

Longwave lamps rarely need replacement, which saves time and money.

Note: I always follow manufacturer guidelines for cleaning and inspection. Proper maintenance extends the life of any infrared lamp and ensures safe operation.

When I choose an infrared lamp, I always start with a clear checklist. This approach helps me focus on what matters most for my needs. I recommend reviewing each point before making a final decision.

Treatment Goals

I identify my main purpose. Some lamps work better for skin health, while others target muscle recovery or general wellness. I match the lamp type to my specific goal.

Usage Frequency

I consider how often I plan to use the lamp. Daily use requires a high-quality device. Occasional use allows for more flexibility in my choice.

Space Constraints

I measure the area where I will install the lamp. Large panels suit spacious rooms. Compact models fit small spaces or portable setups.

Warranty and Support

I check the warranty details. Reliable customer support adds value and peace of mind. I prefer brands that offer comprehensive coverage.

Additional Features

I look for built-in timers, adjustable power settings, and combination wavelengths. These features improve my experience and make the lamp easier to use.

Tip: I always compare several models using this checklist. This method ensures I select the lamp that matches my needs and expectations.

I use a simple flowchart to guide my decision. This process helps me narrow down the options and choose the best infrared lamp for my situation.

Step | Question | If Yes | If No |

|---|---|---|---|

1 | Do I need rapid, intense heat for industrial or medical use? | Choose Shortwave IR | Go to Step 2 |

2 | Is balanced heat and moderate penetration important for my application? | Choose Mediumwave IR | Go to Step 3 |

3 | Is gentle, comfort heating my main priority for home or hospitality? | Choose Longwave IR | Go to Step 4 |

4 | Do I have space limitations or need portable options? | Select compact or portable models | Consider panel size |

5 | Will I use the lamp daily or require advanced features? | Invest in high-quality, feature-rich models | Basic models may suffice |

Note: I always follow this flowchart to simplify my selection process. By answering each question, I quickly identify the lamp type and features that suit my needs.

This decision guide helps me stay organized and confident when choosing an infrared lamp. I encourage readers to use both the checklist and flowchart for a smooth selection experience.

When I work in automotive refinishing or industrial painting, I rely on an infrared paint curing lamp to achieve professional results. This tool uses targeted infrared energy to dry and harden paint layers quickly. I often use it in auto body shops, manufacturing plants, and even small workshops. The lamp directs heat precisely onto the painted surface, which speeds up the drying process and ensures a smooth, durable finish.

I find the infrared paint curing lamp especially useful for spot repairs and panel work. It allows me to cure small areas without affecting the rest of the vehicle or workspace. I can adjust the lamp’s position and intensity to match the size and type of the job. This flexibility makes it a valuable asset for both large-scale production and custom projects.

Here are some common applications where I use this technology:

Automotive body shops for spot repairs and full panel painting

Industrial assembly lines for rapid paint drying

Furniture manufacturing for finishing wood surfaces

DIY workshops for small-scale projects

Tip: I always check the paint manufacturer’s recommendations before using the lamp. This ensures optimal results and prevents damage to sensitive finishes.

I have seen many advantages when I use an infrared paint curing lamp. The most significant benefit is the reduction in drying time. Traditional air drying can take hours, but infrared technology completes the process in minutes. This efficiency helps me increase productivity and reduce downtime in my workflow.

Another benefit is the quality of the finish. The lamp provides even heat distribution, which prevents runs, sags, and dust contamination. I notice that the cured paint has a harder, more resilient surface. This durability stands up well to daily wear and tear.

Here is a table summarizing the key benefits I experience:

Benefit | Description |

|---|---|

Faster Drying | Reduces drying time from hours to minutes |

Improved Finish Quality | Ensures smooth, even, and durable surfaces |

Energy Efficiency | Uses less energy than conventional ovens |

Space Saving | Compact design fits in small workshops |

Versatility | Suitable for various paint types and surfaces |

I also appreciate the energy savings. The lamp targets only the area that needs curing, which lowers overall power consumption. Its compact size means I can use it in tight spaces or move it easily between jobs.

Note: I always wear protective gear and follow safety guidelines when operating the lamp. Proper use ensures both safety and the best possible results.

When I select an infrared lamp, I always match the type to my heating needs. Shortwave lamps deliver fast, deep heat for industrial tasks. Mediumwave models balance comfort and efficiency in commercial settings. Longwave lamps create gentle warmth for homes and hospitality. I recommend reviewing your environment and budget before making a choice. Use my decision guide and comparison overview to find the best fit.

I see shortwave lamps deliver intense, fast heat for industrial tasks. Mediumwave lamps balance comfort and efficiency in commercial settings. Longwave lamps provide gentle warmth, perfect for homes and hospitality. I always match the lamp type to my specific heating needs.

I use infrared lamps for muscle and joint pain relief. Shortwave and mediumwave models work best for deeper penetration. I recommend following safety guidelines and consulting a healthcare professional before starting any home therapy.

I clean the lamp surface regularly and check connections for wear. I follow manufacturer instructions for maintenance. I replace shortwave lamps more often due to their shorter lifespan. Mediumwave and longwave lamps require less frequent attention.

I install longwave infrared lamps in areas where children and pets spend time. These lamps operate at lower temperatures and pose minimal risk. I always follow safety guidelines and keep lamps out of reach to prevent accidental contact.

I look for adjustable power settings, built-in timers, and safety certifications. I check the warranty and customer support options. I choose models with combination wavelengths for versatile use. I always compare several products before making a decision.

I use shortwave infrared lamps in industrial settings to maximize energy savings. These lamps convert most electrical input into usable heat. Mediumwave and longwave models also improve efficiency in homes and businesses. I always calculate total cost of ownership before purchasing.